🚀 Ctrl-Food

Fully autonomous fast-food production systems

Robotic cooking, assembly, and

cleaning - containerized, modular, ans staff-free

🎥 Demo Videos

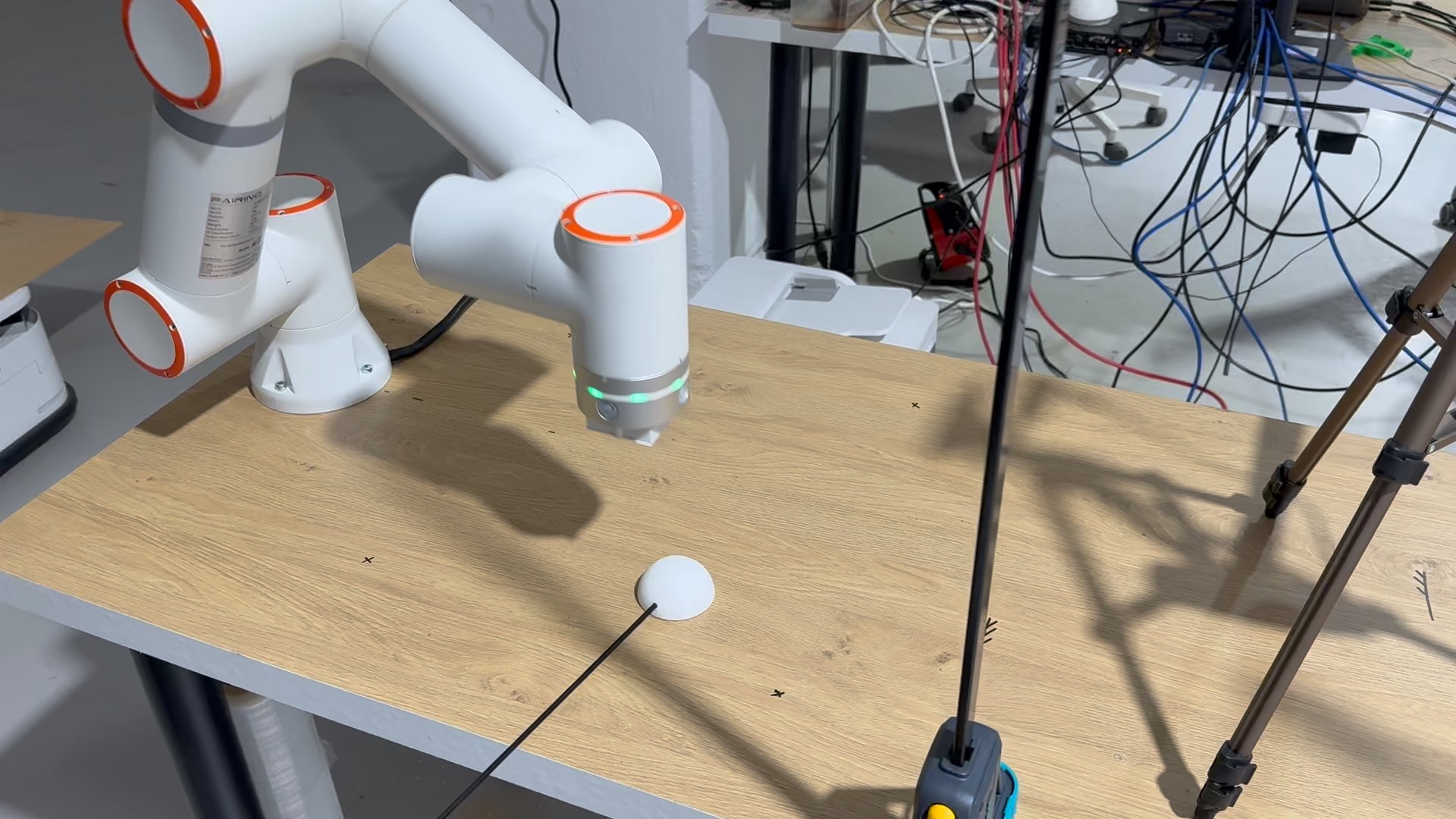

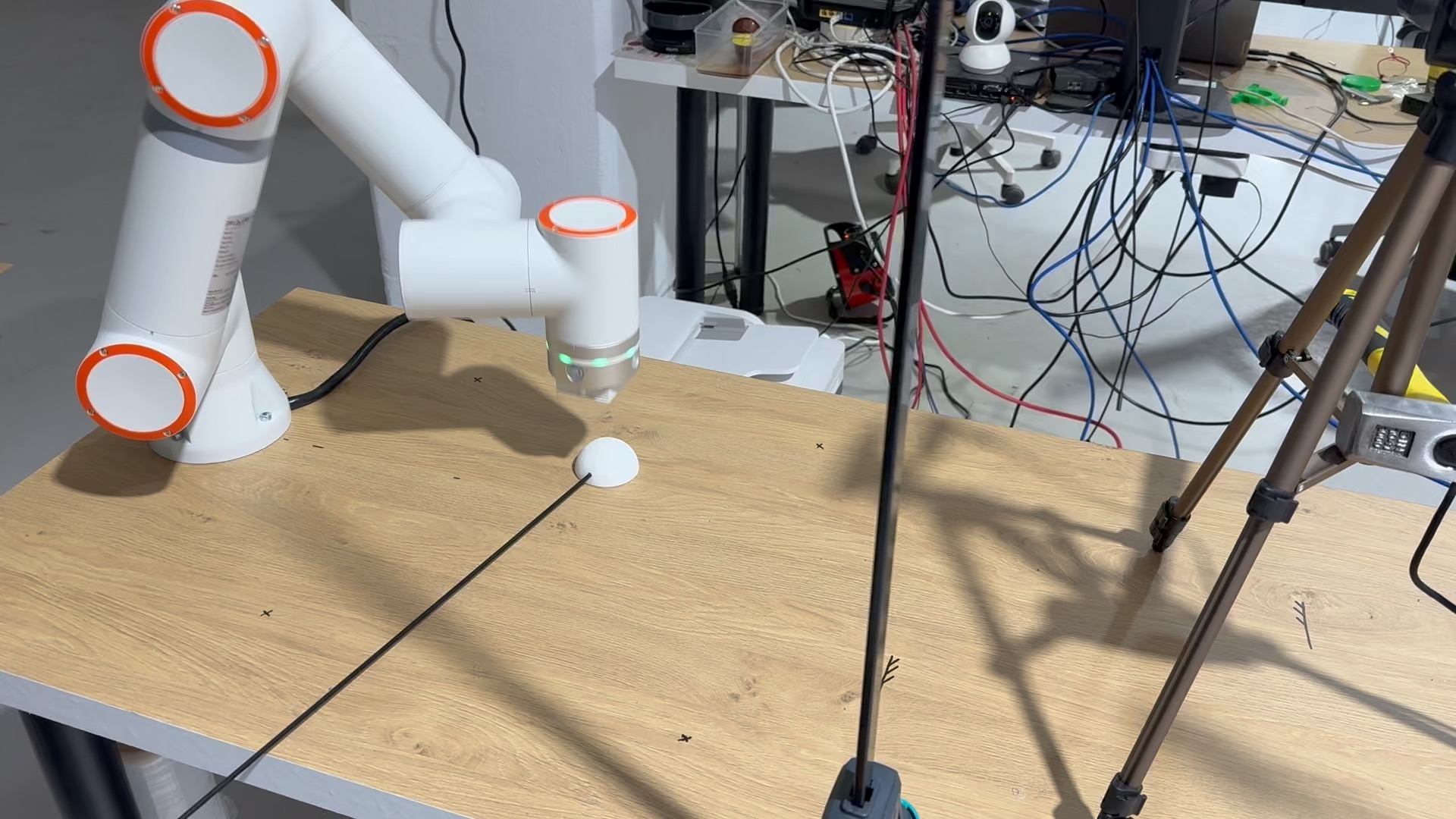

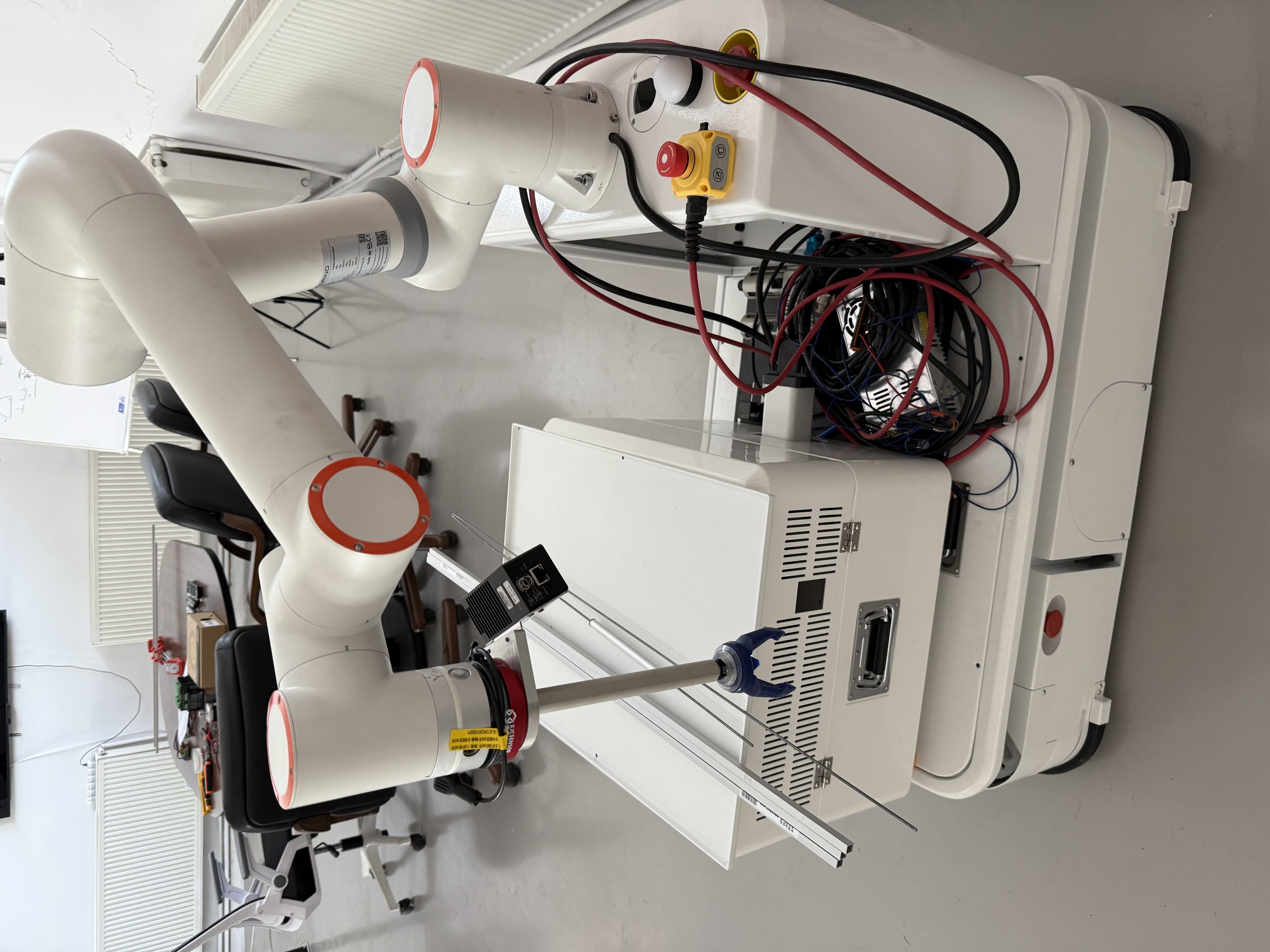

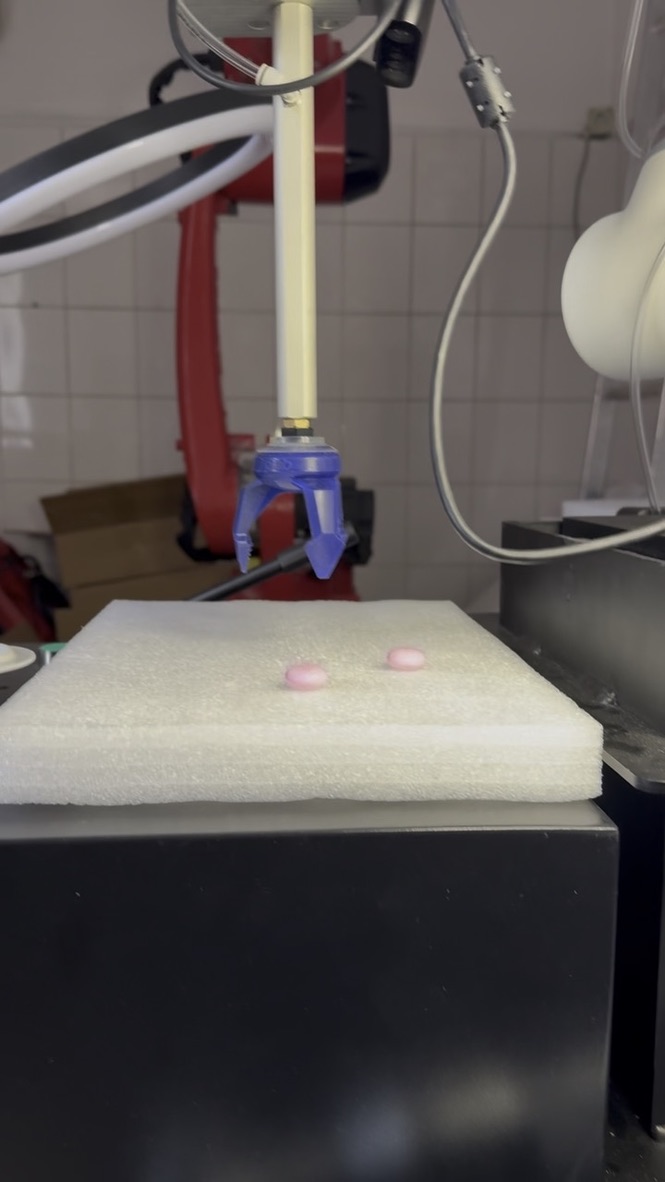

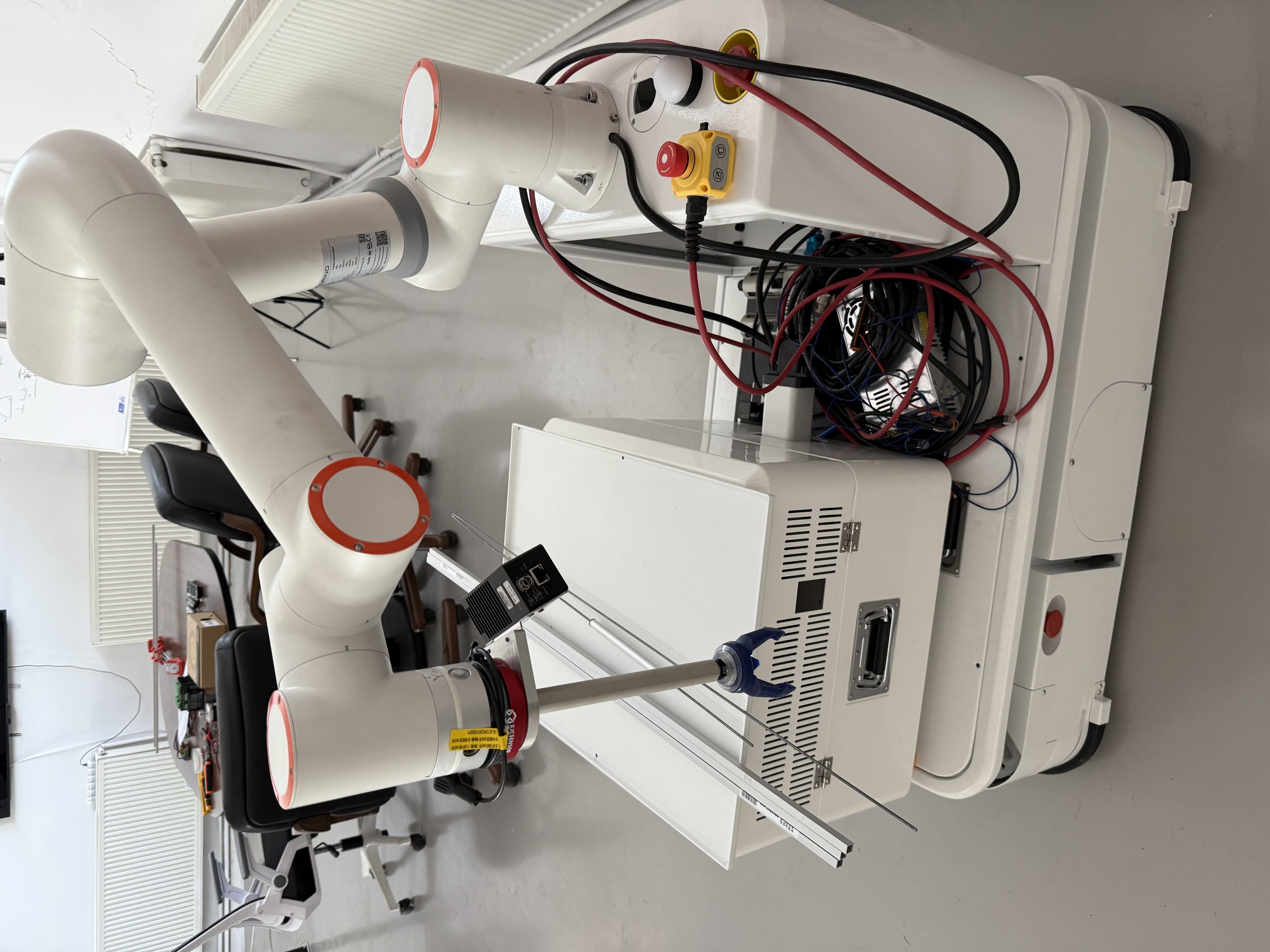

1. Picking

2. Wrapping

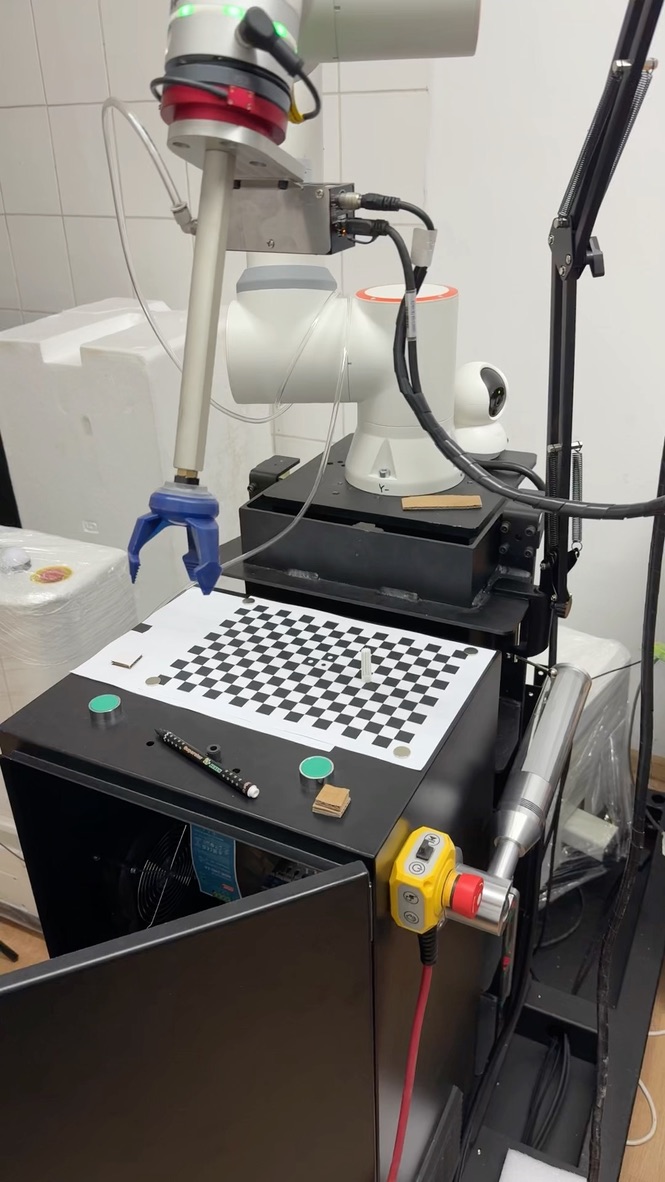

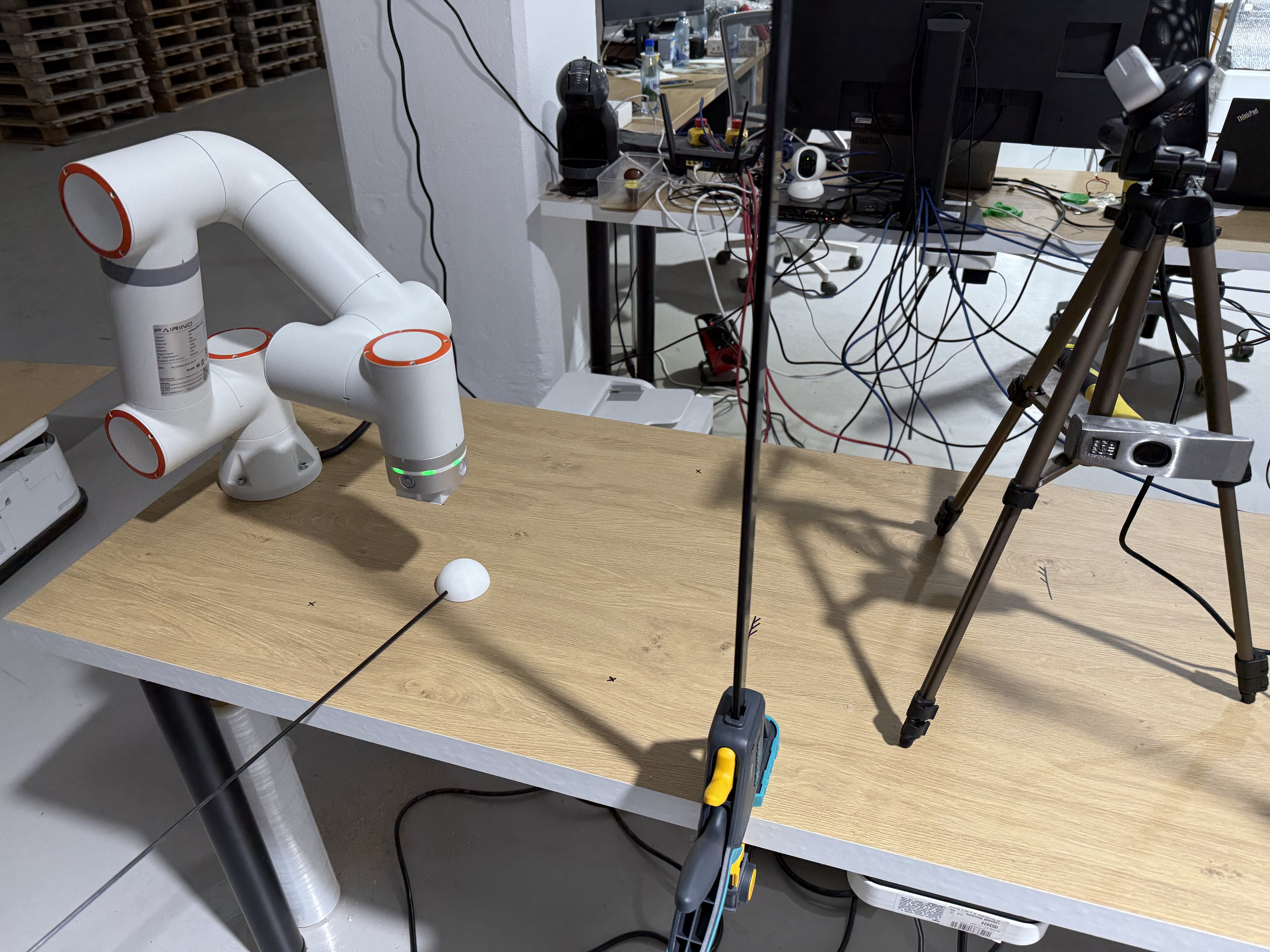

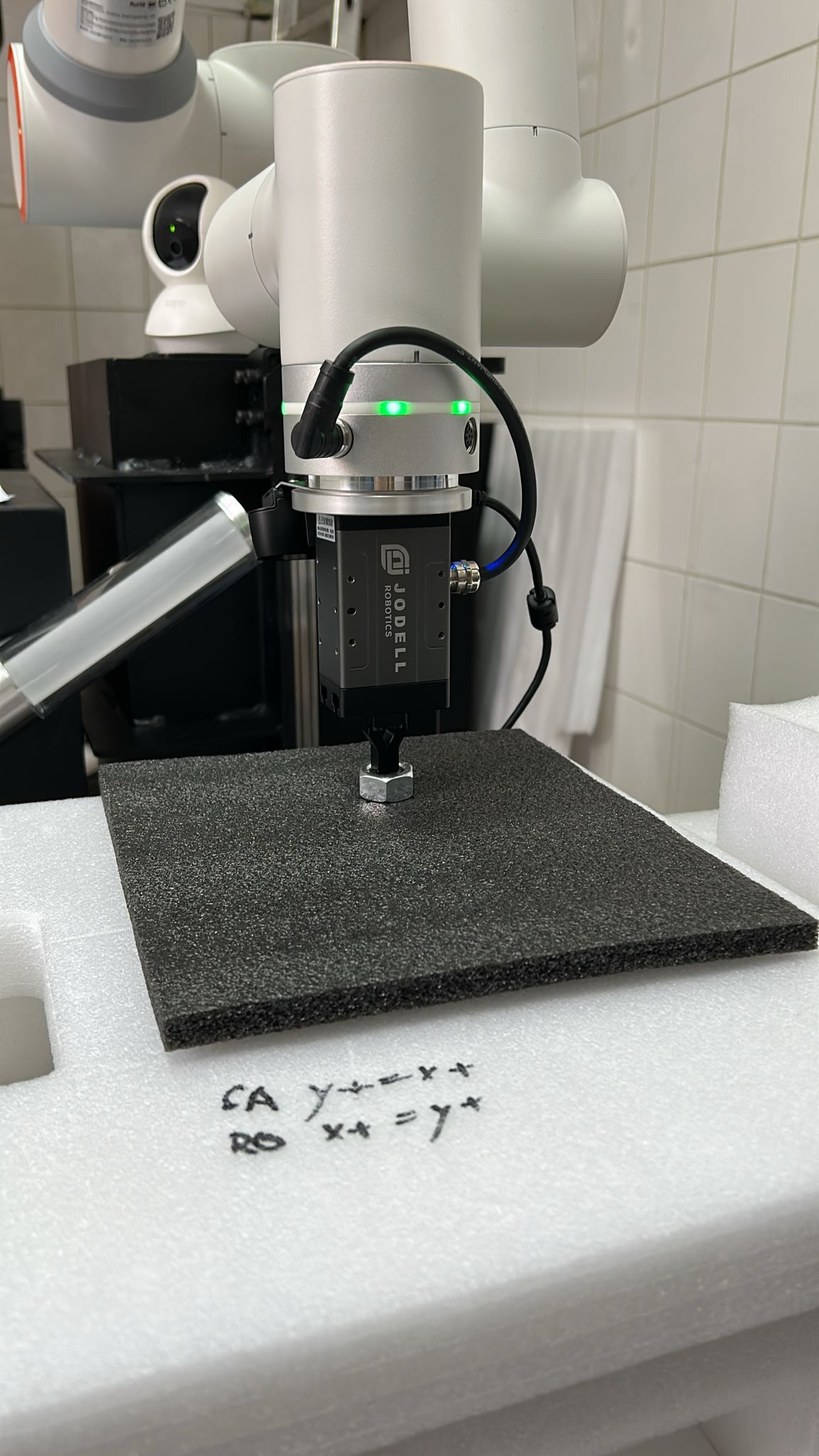

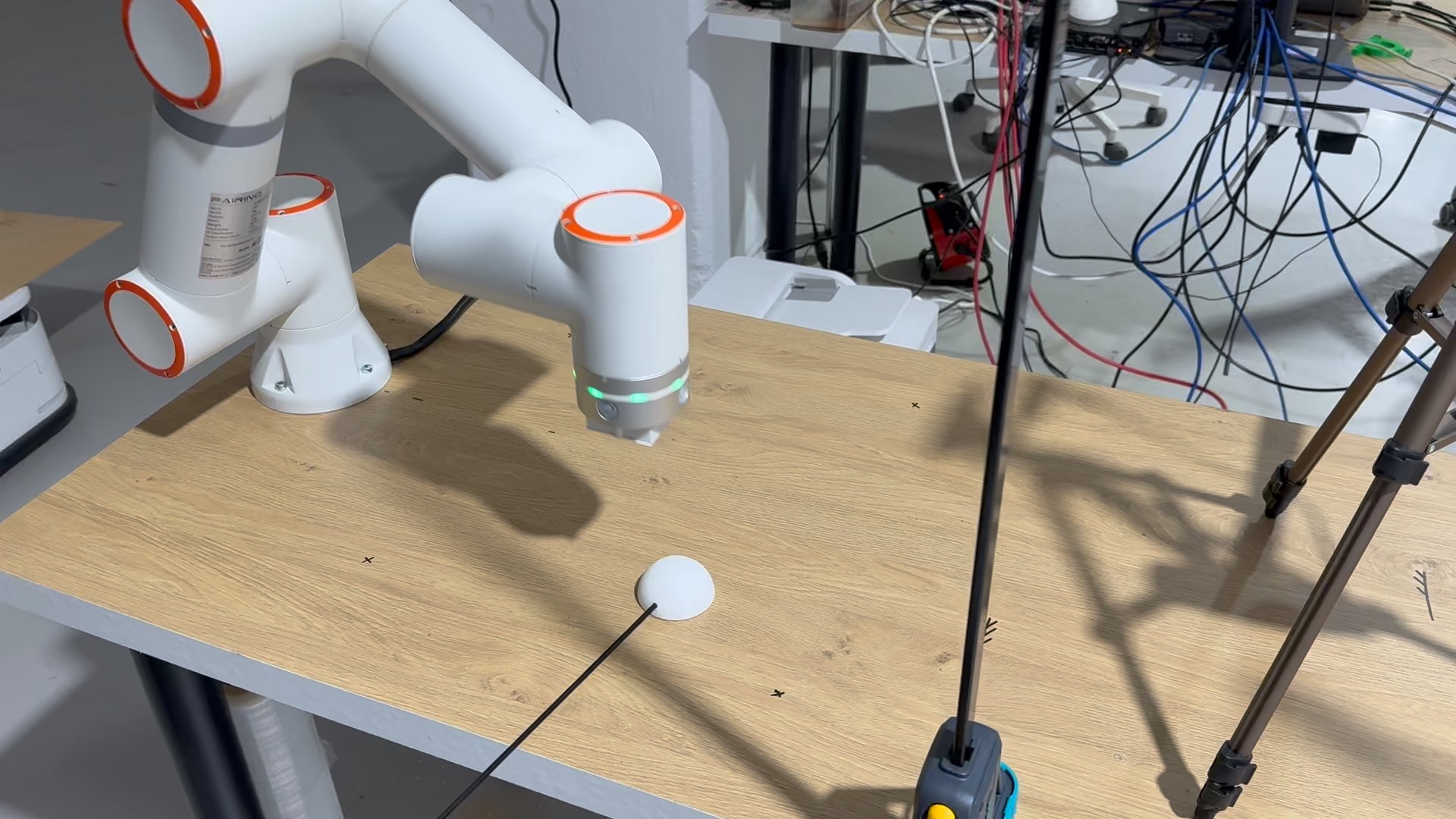

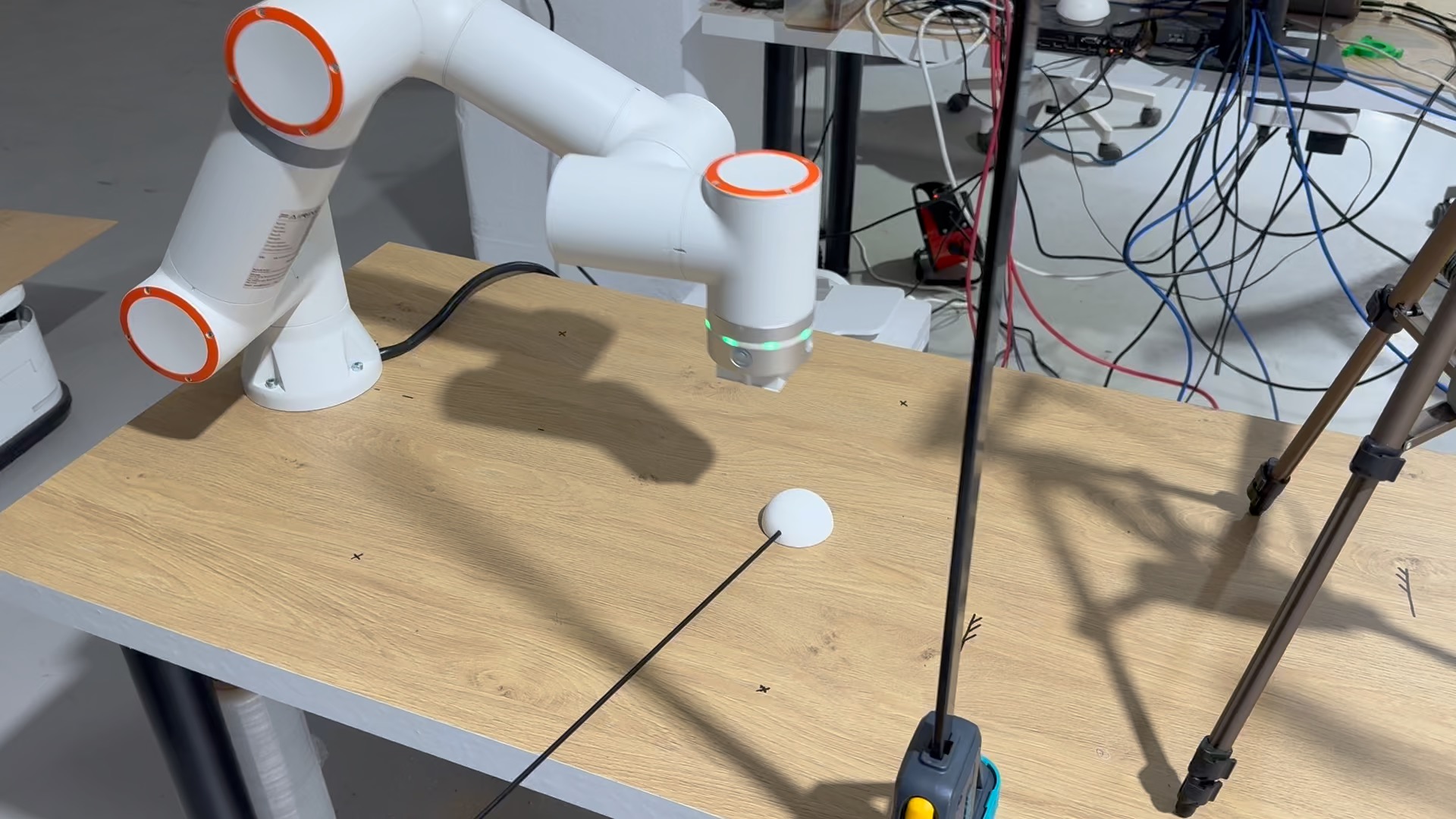

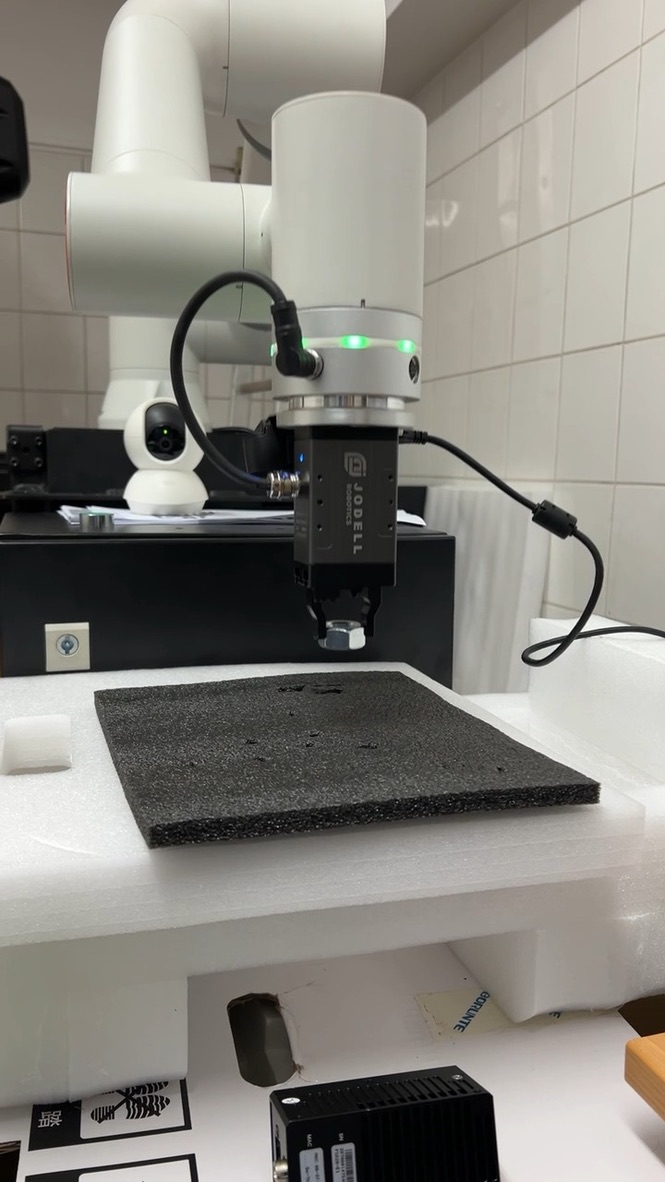

3. Calibration

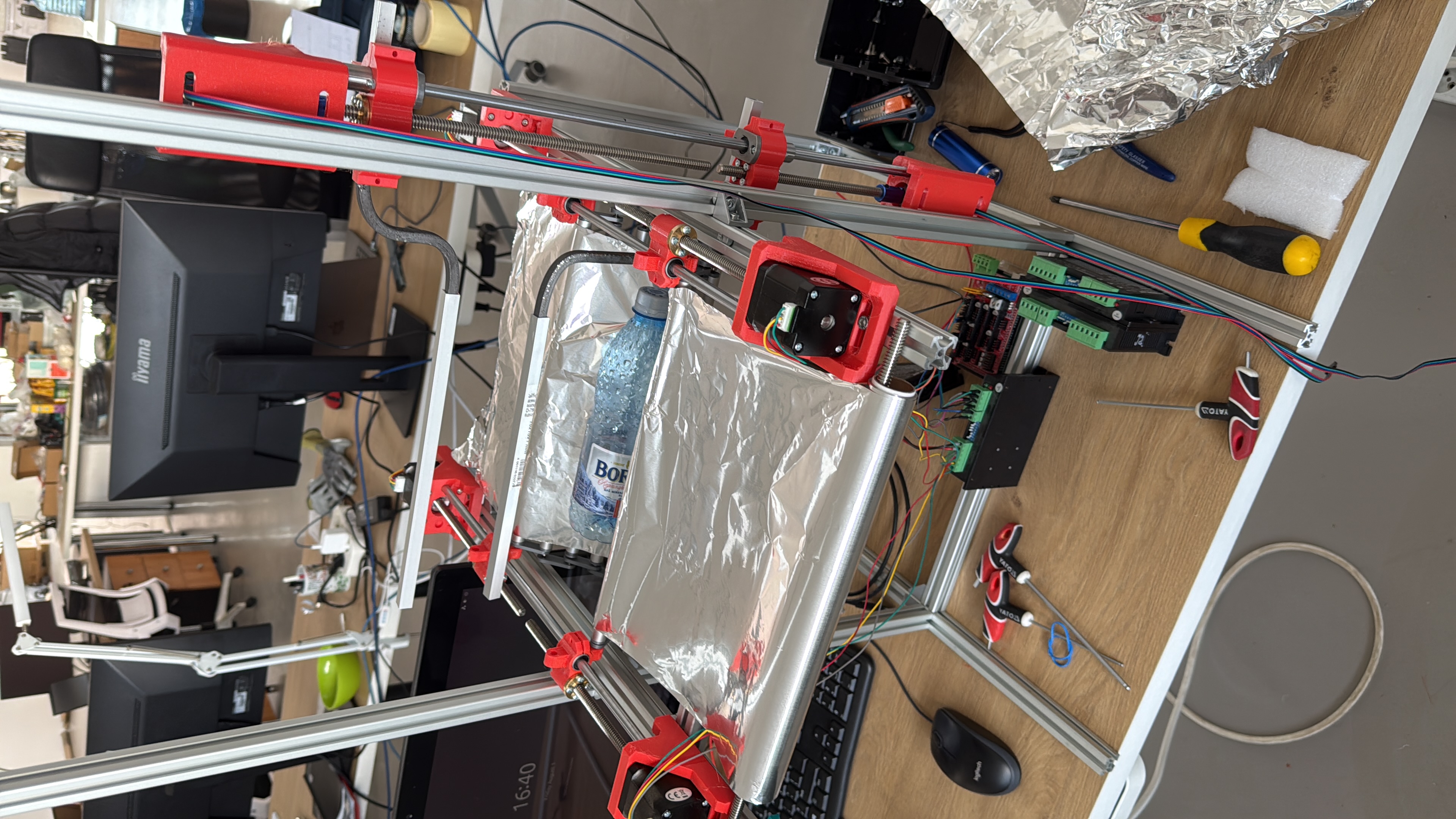

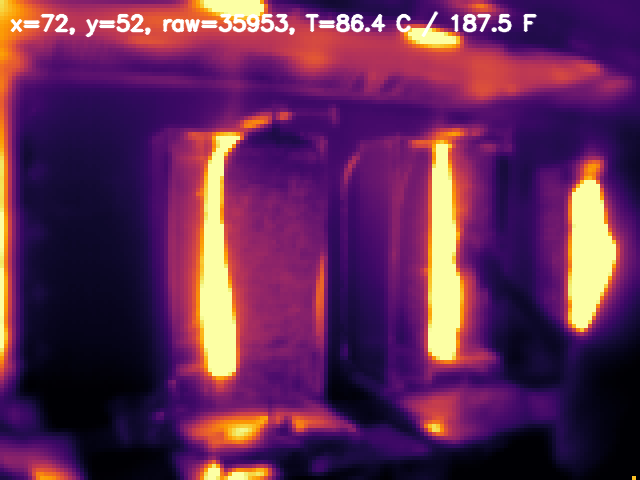

4. Thermal

📸 Demo Pictures

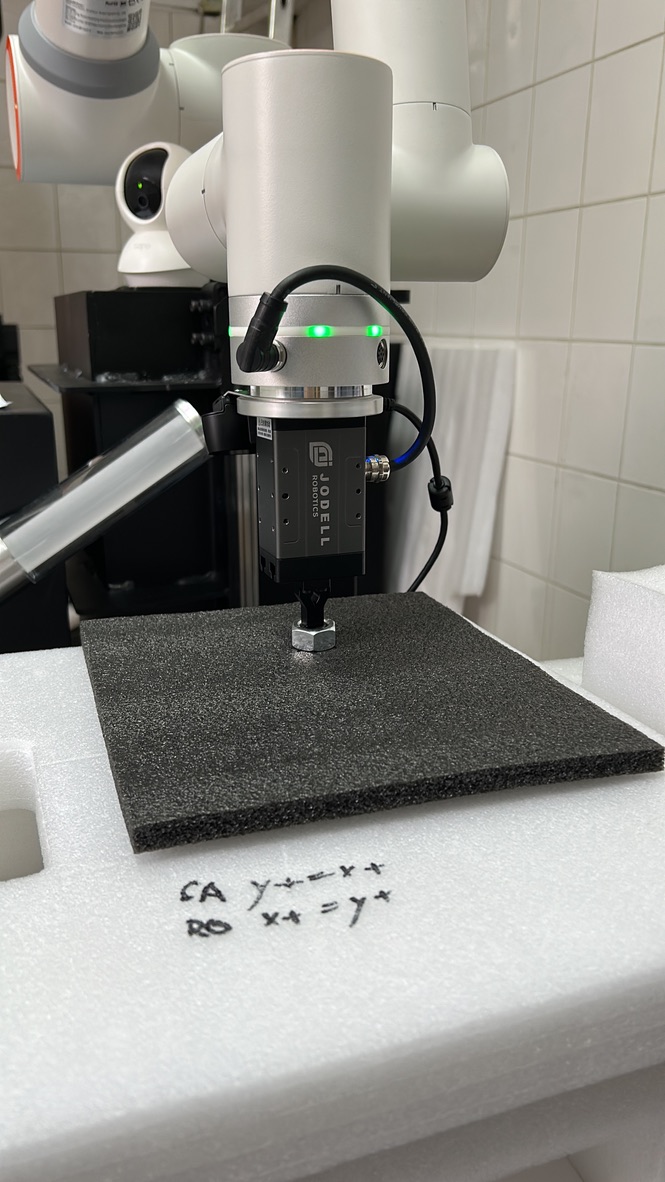

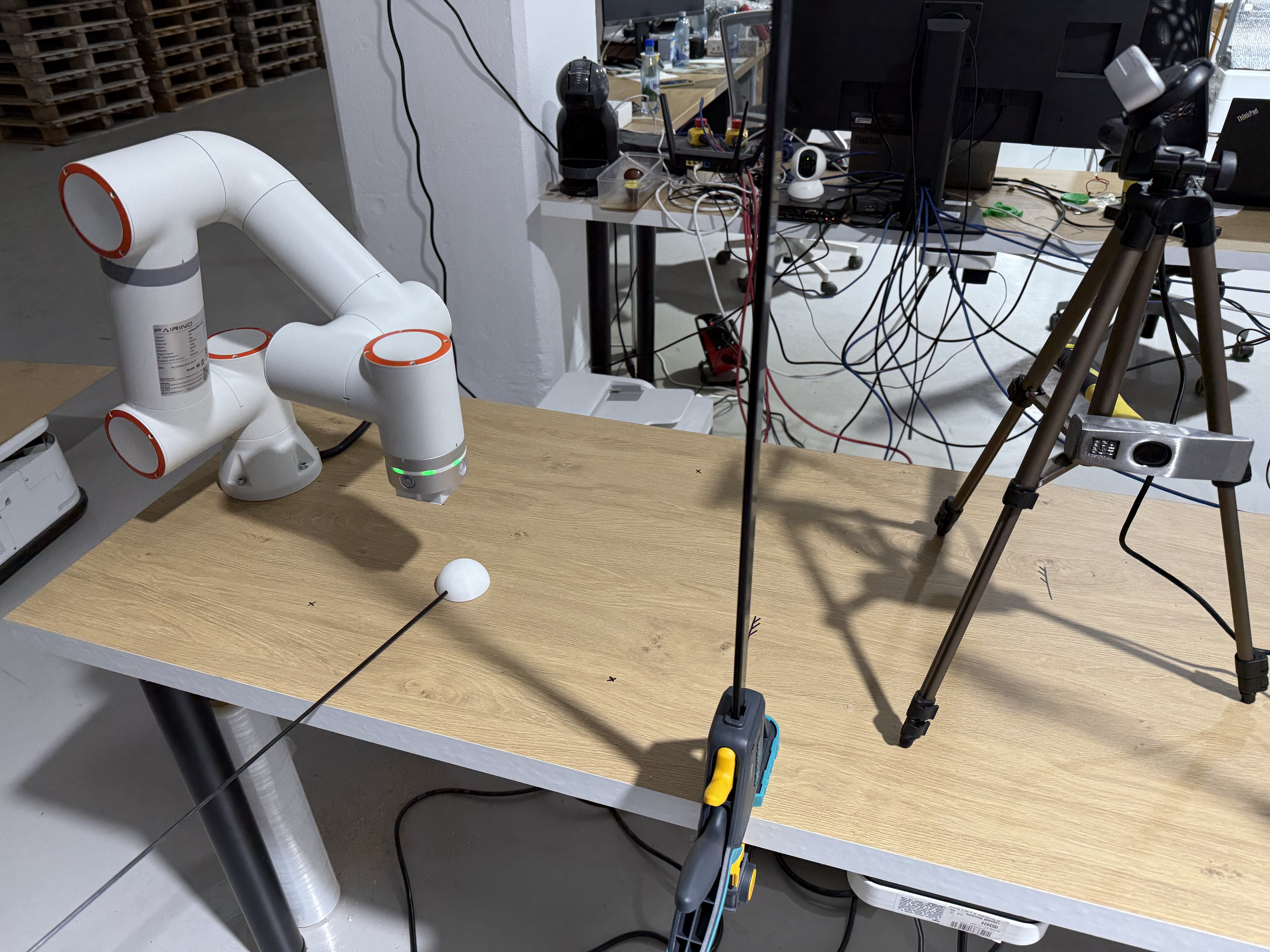

1. Picking

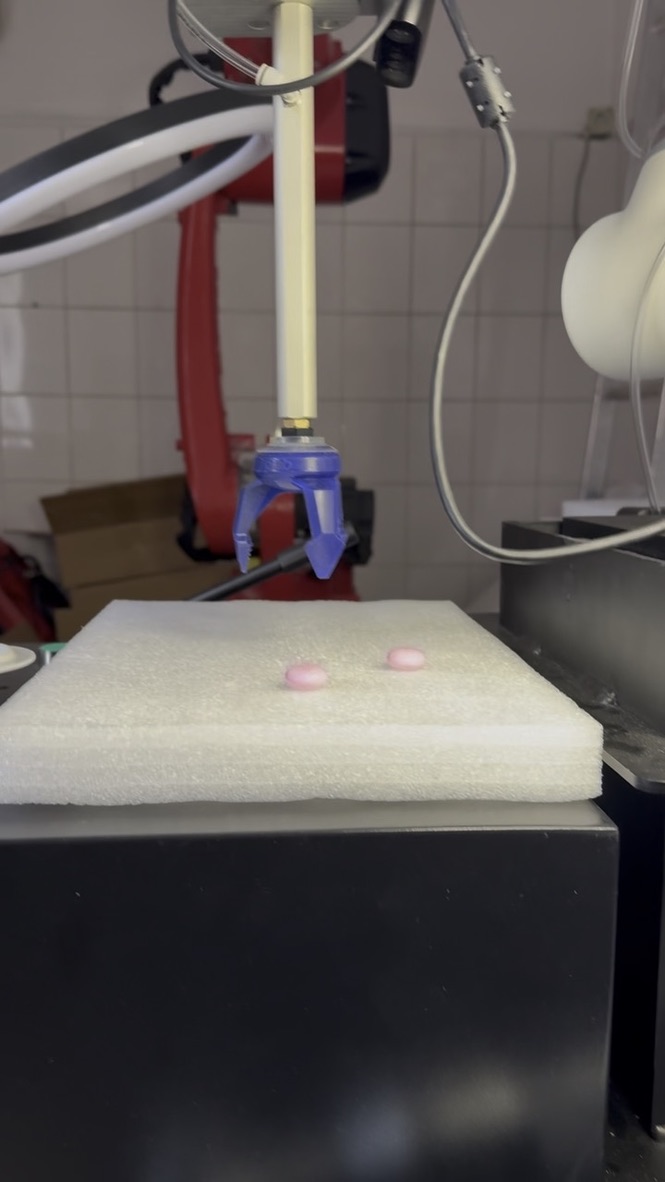

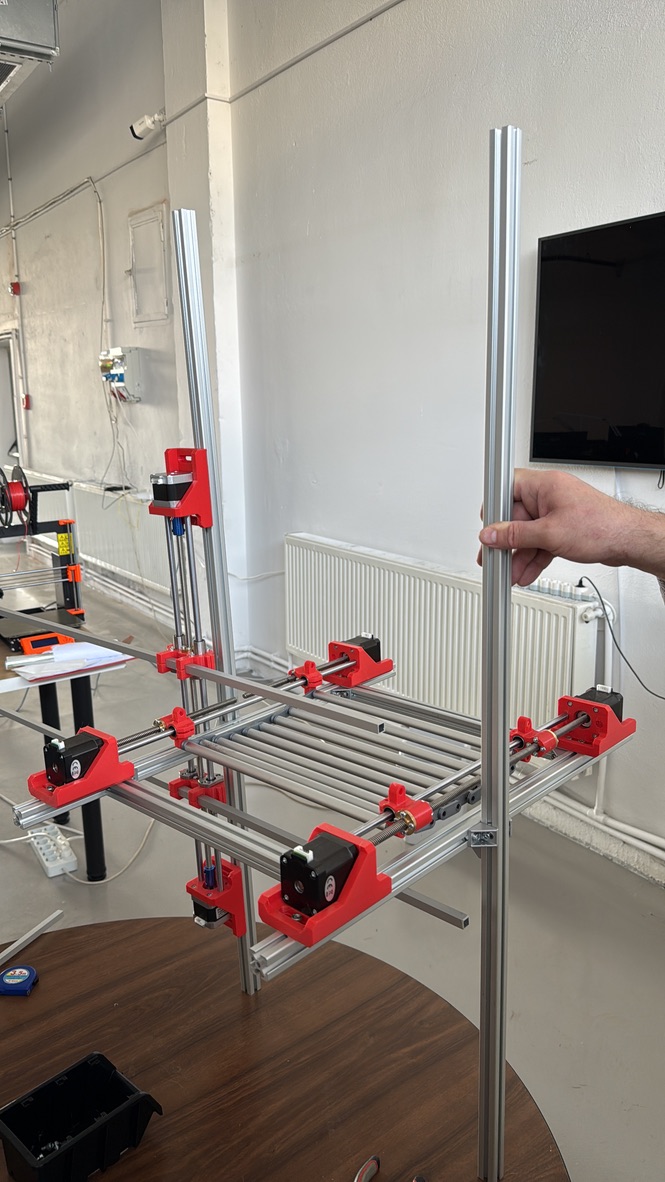

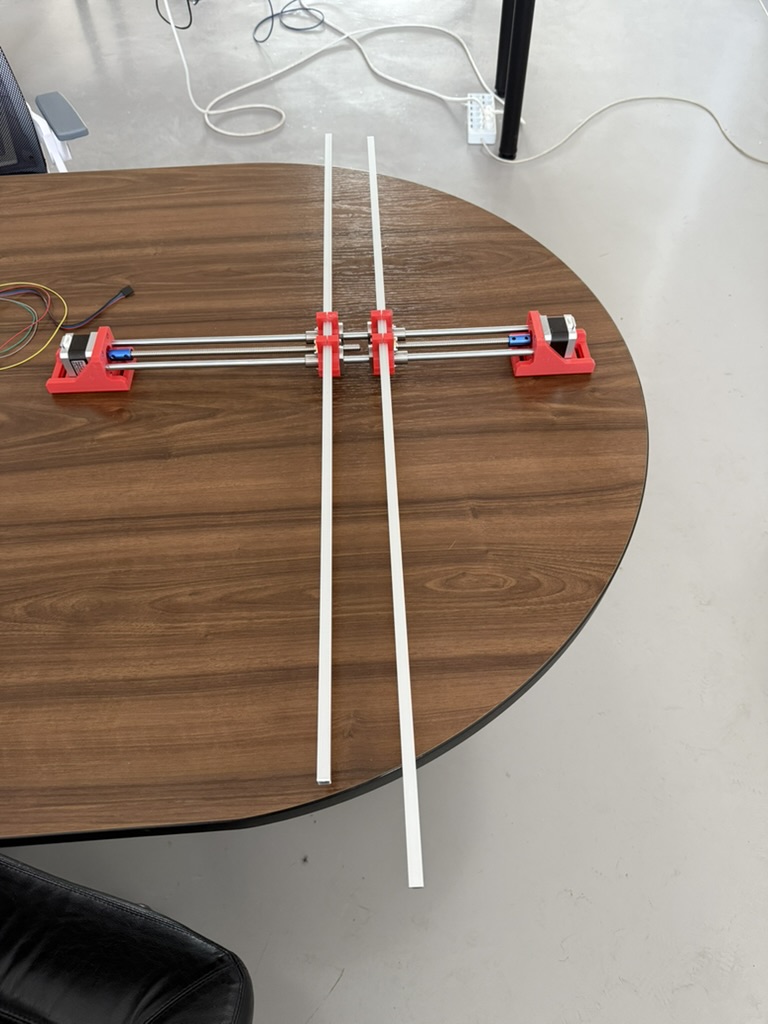

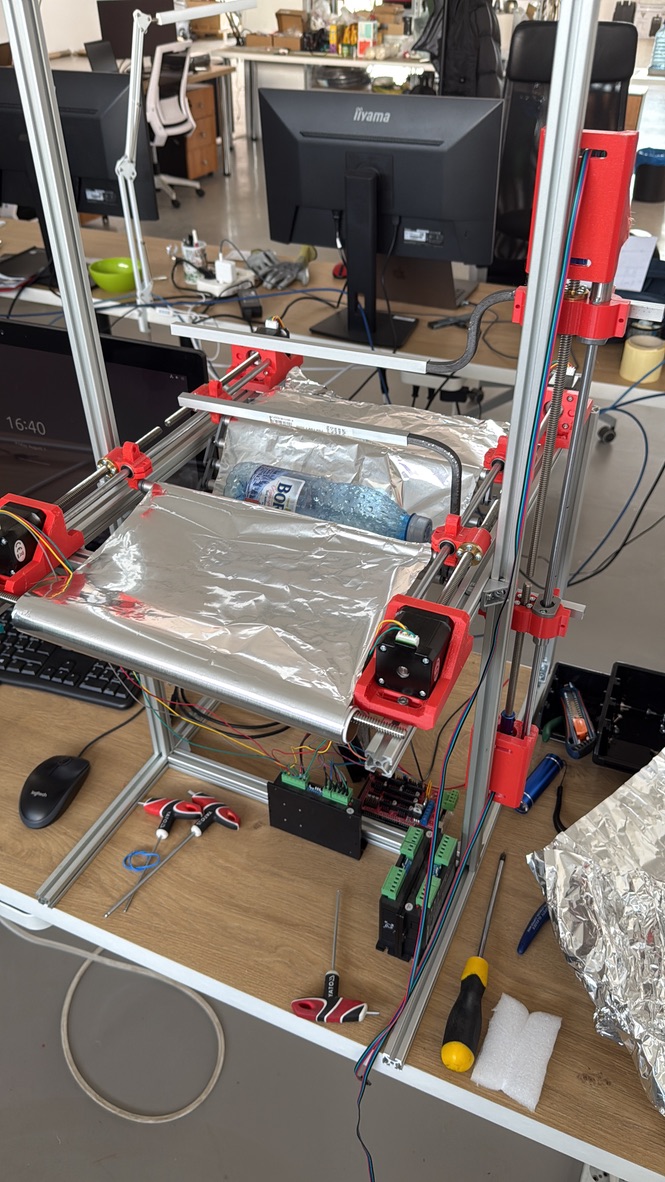

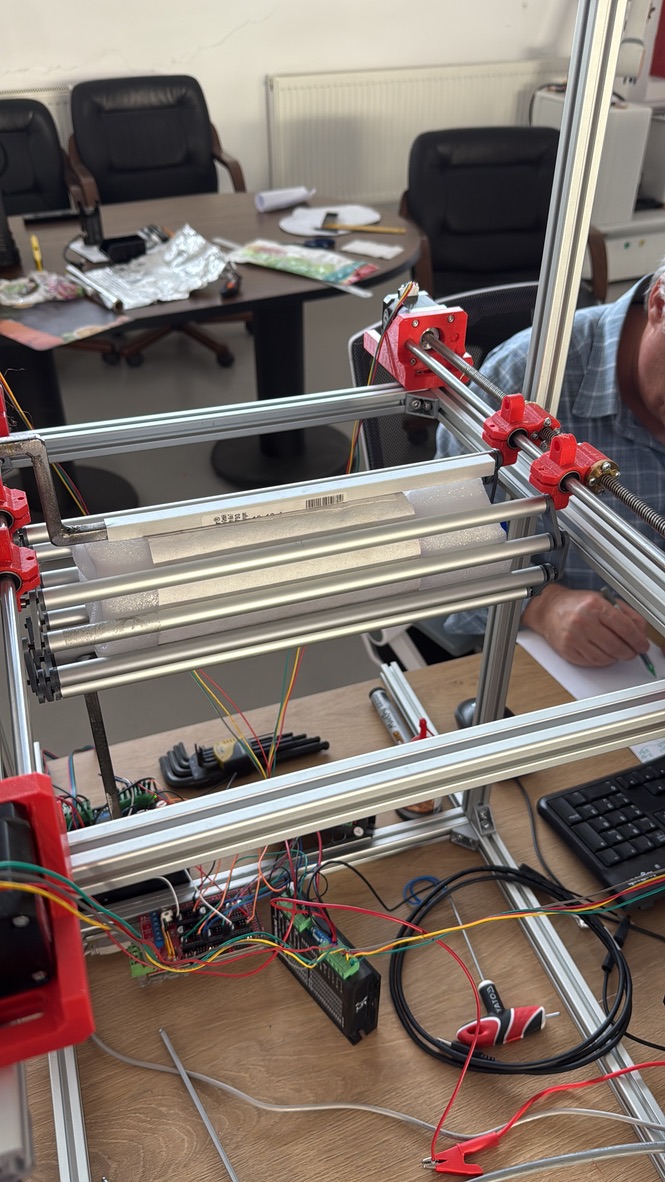

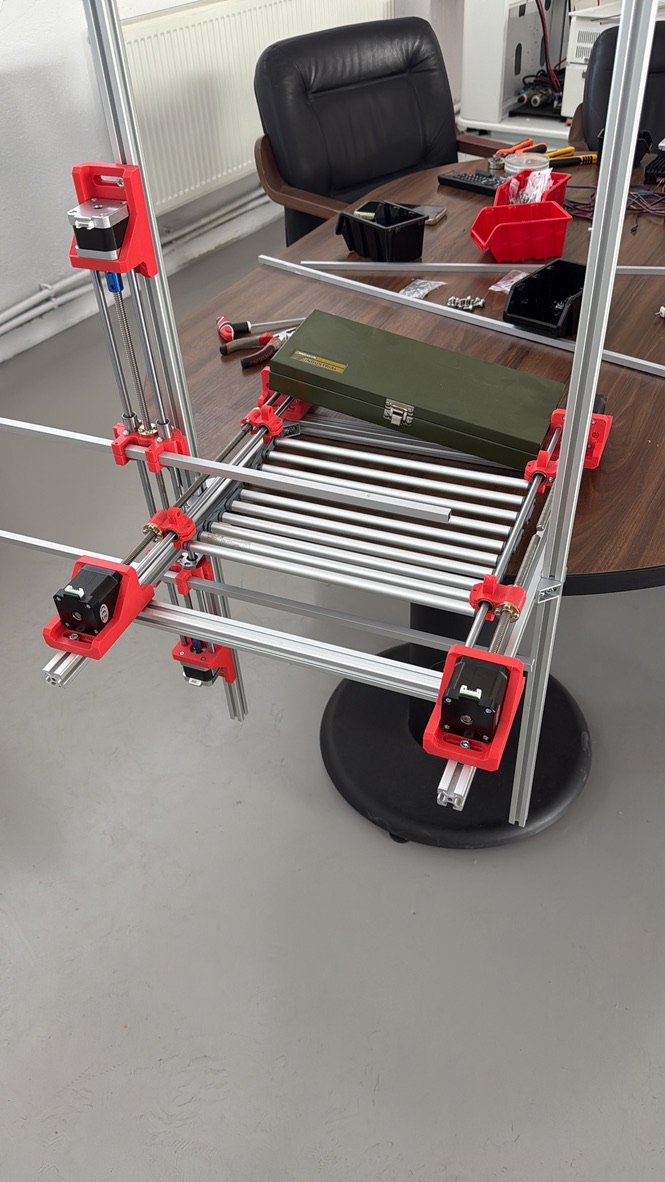

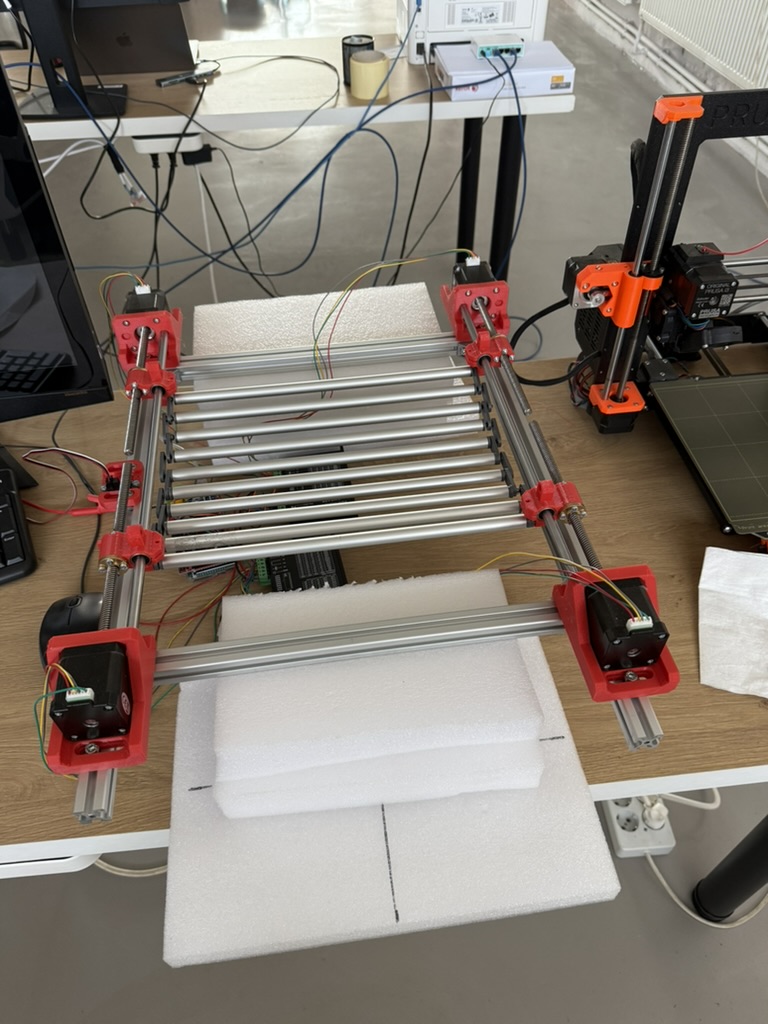

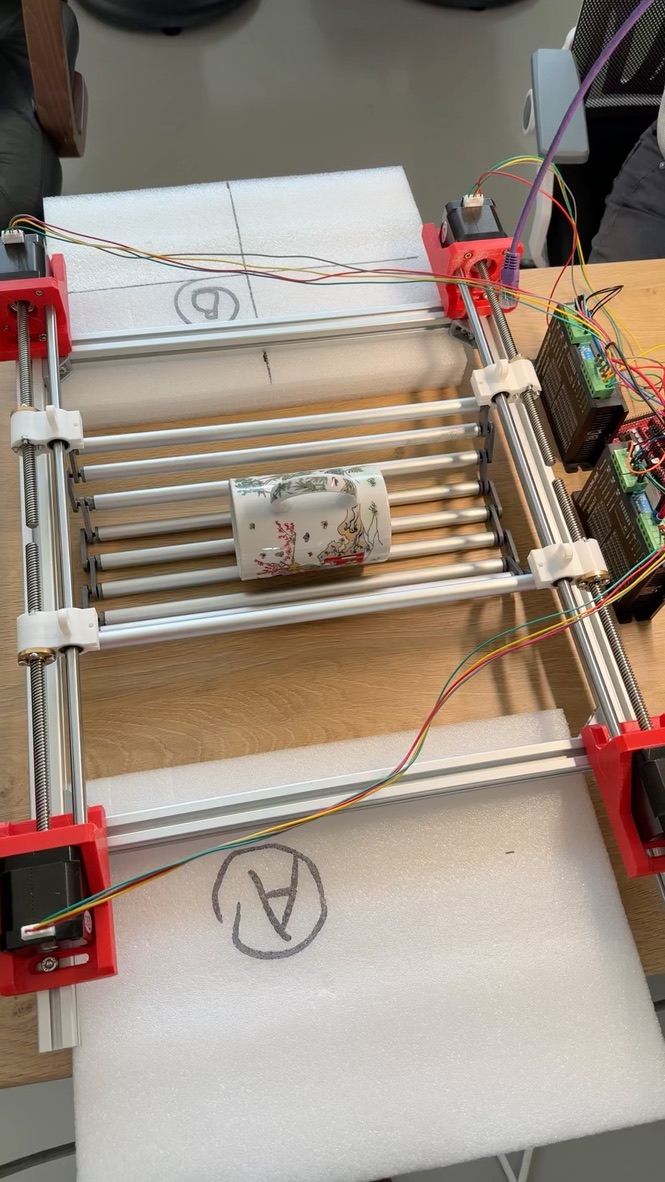

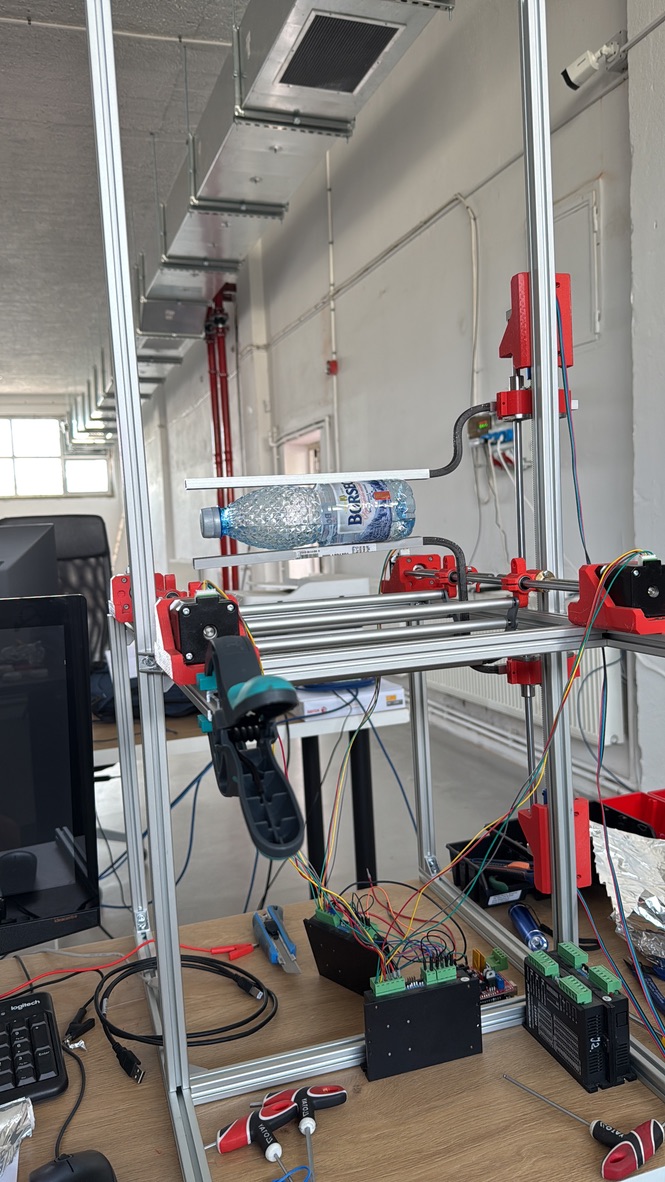

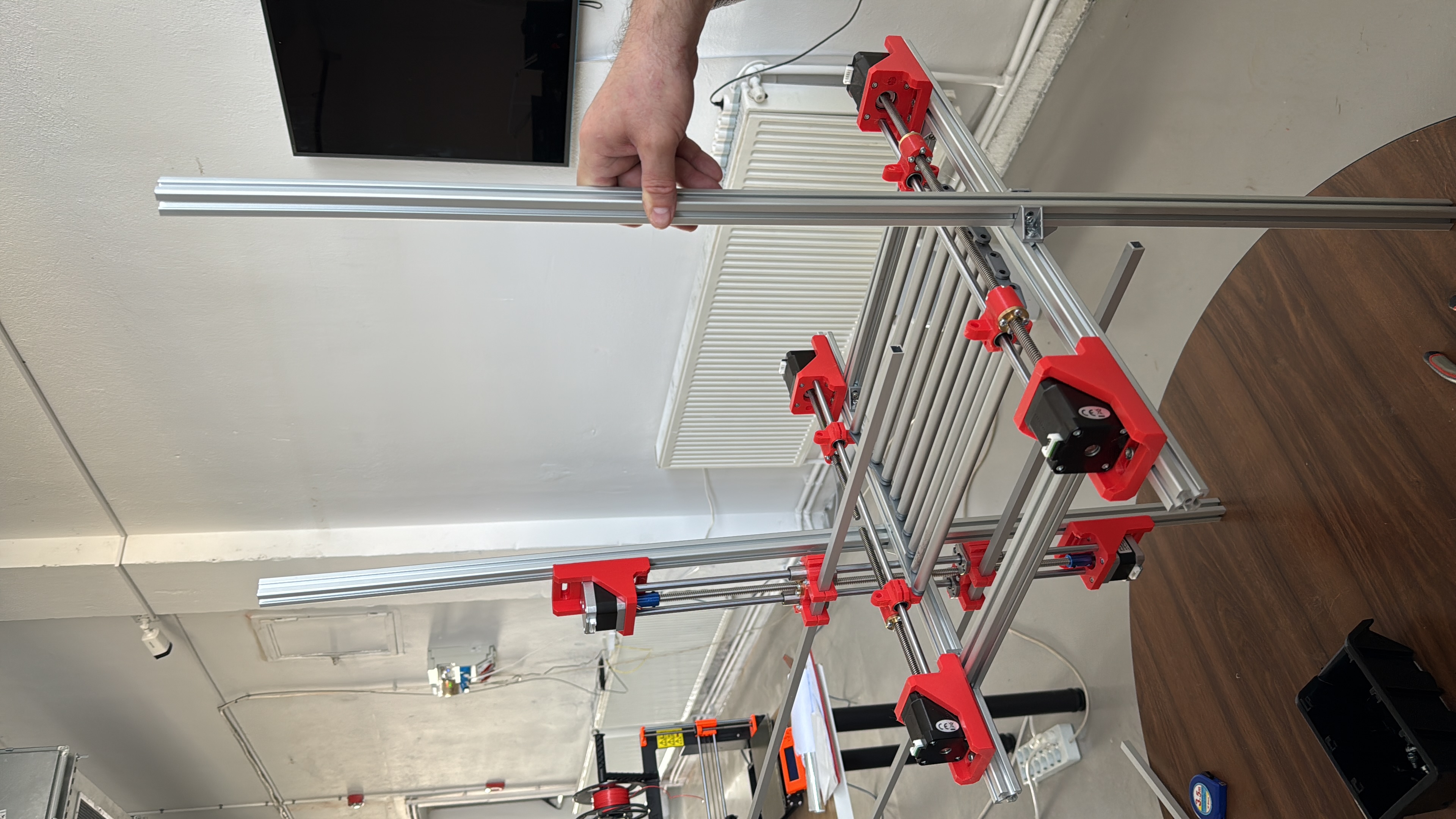

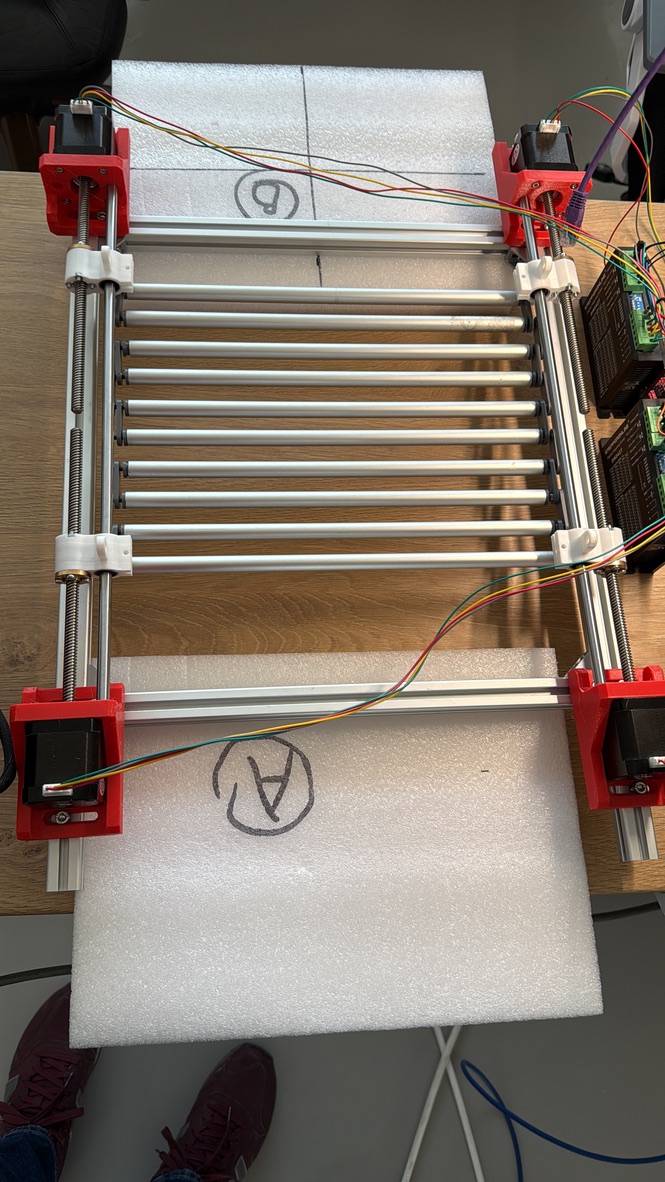

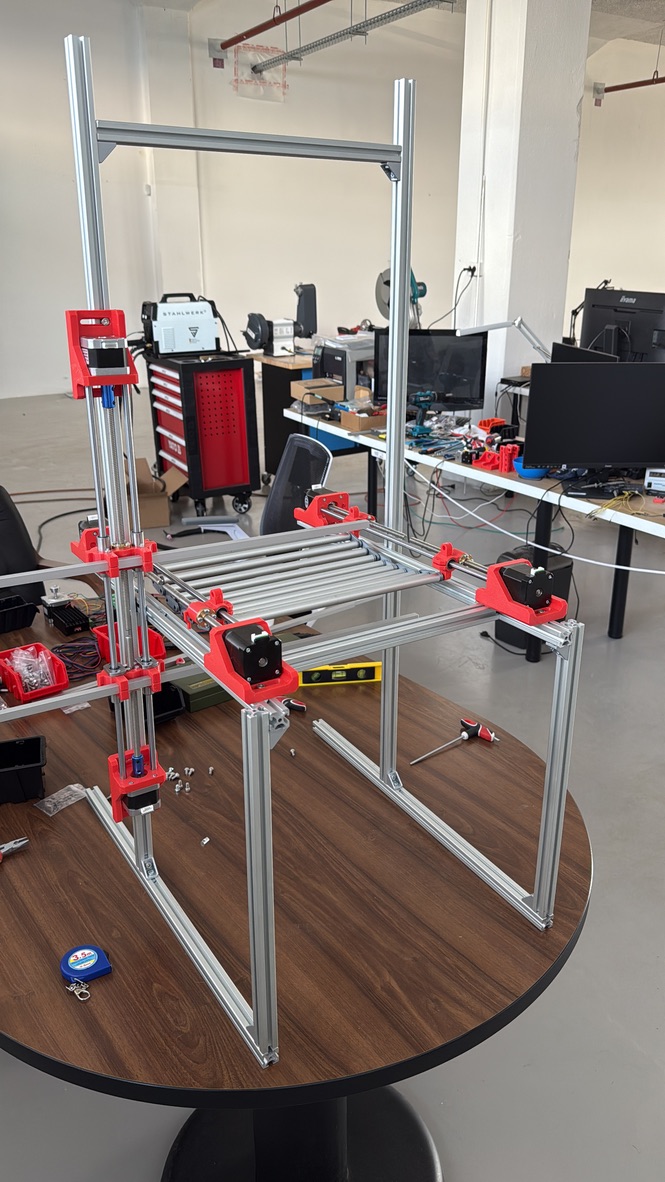

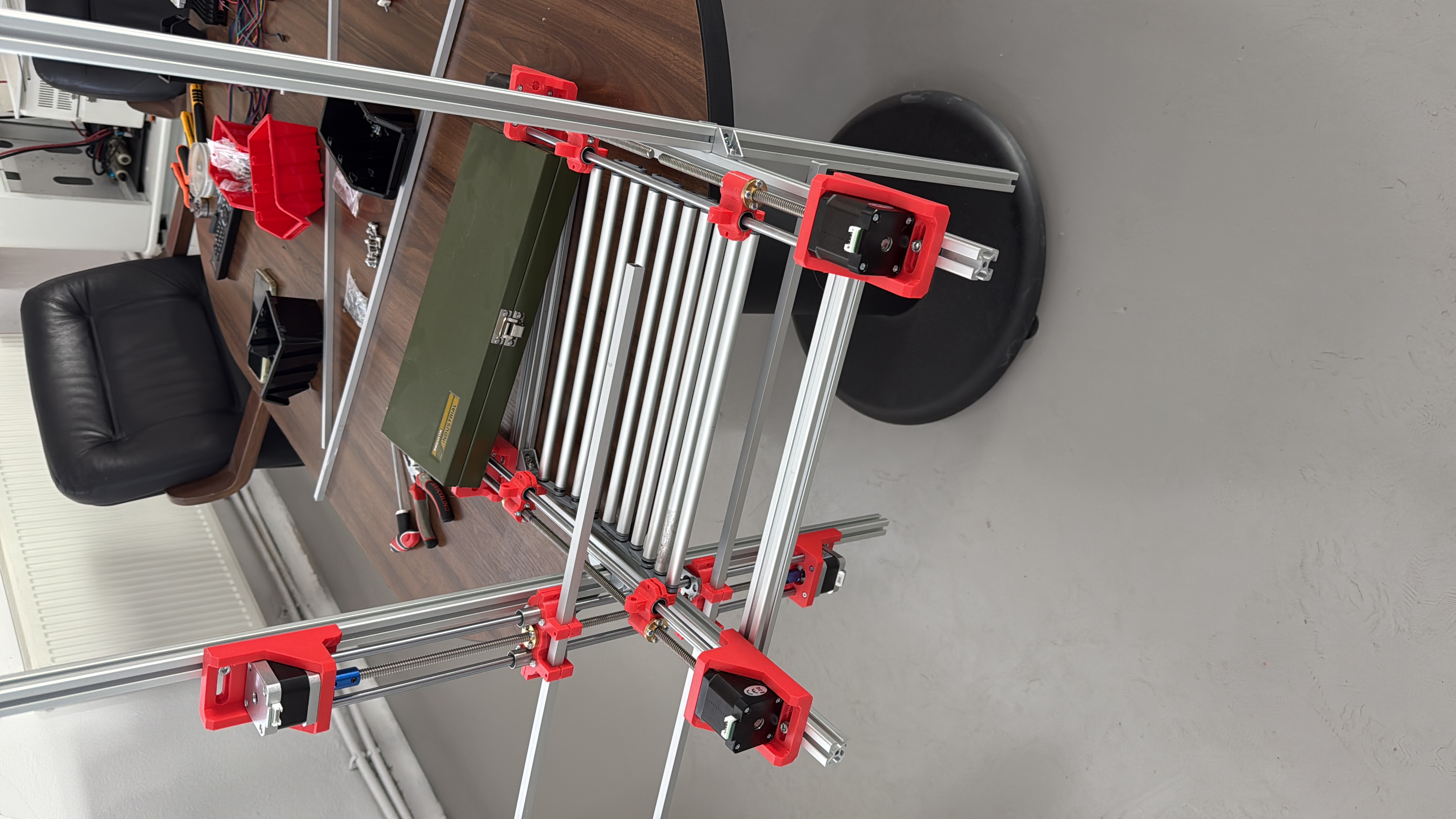

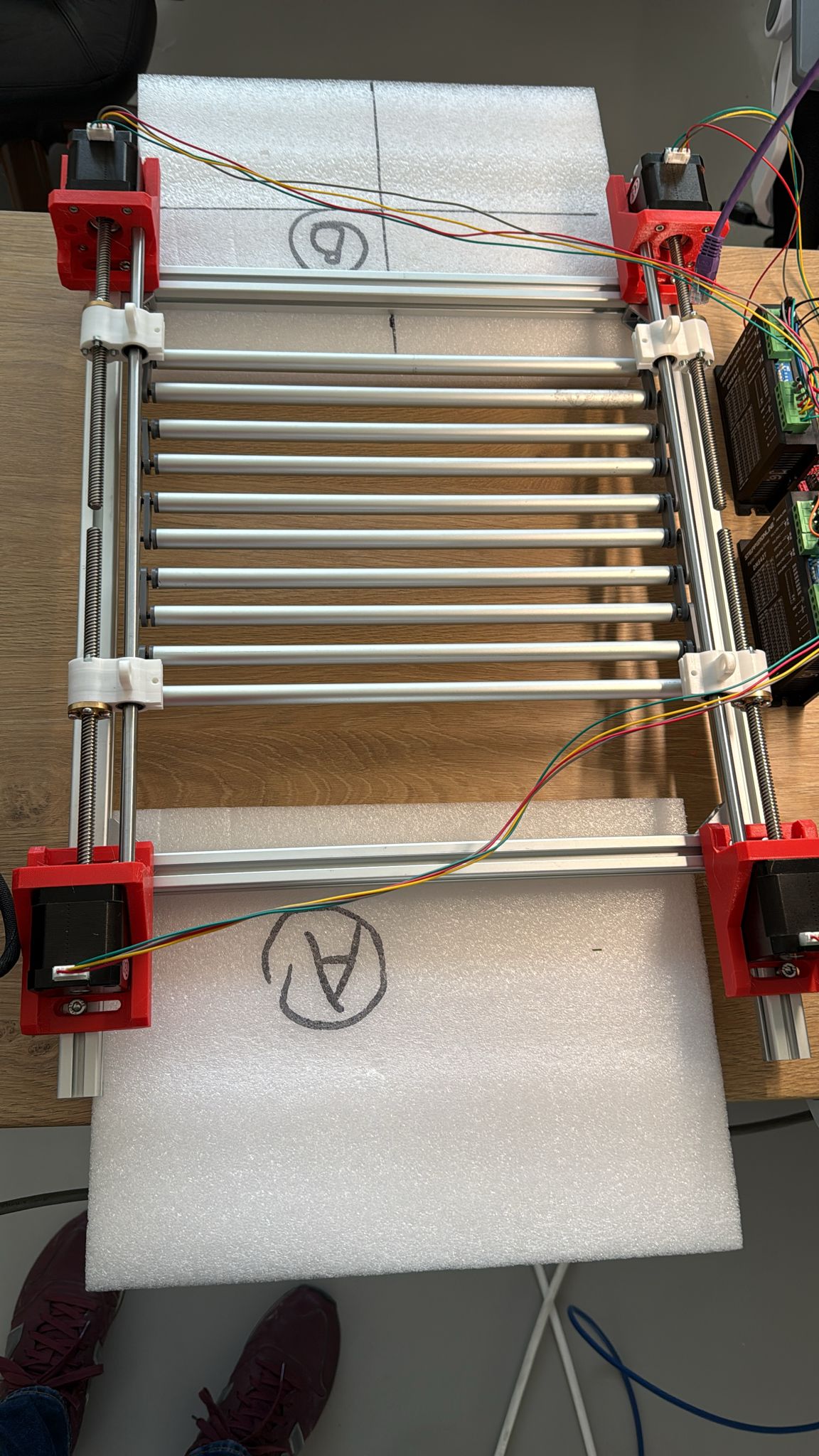

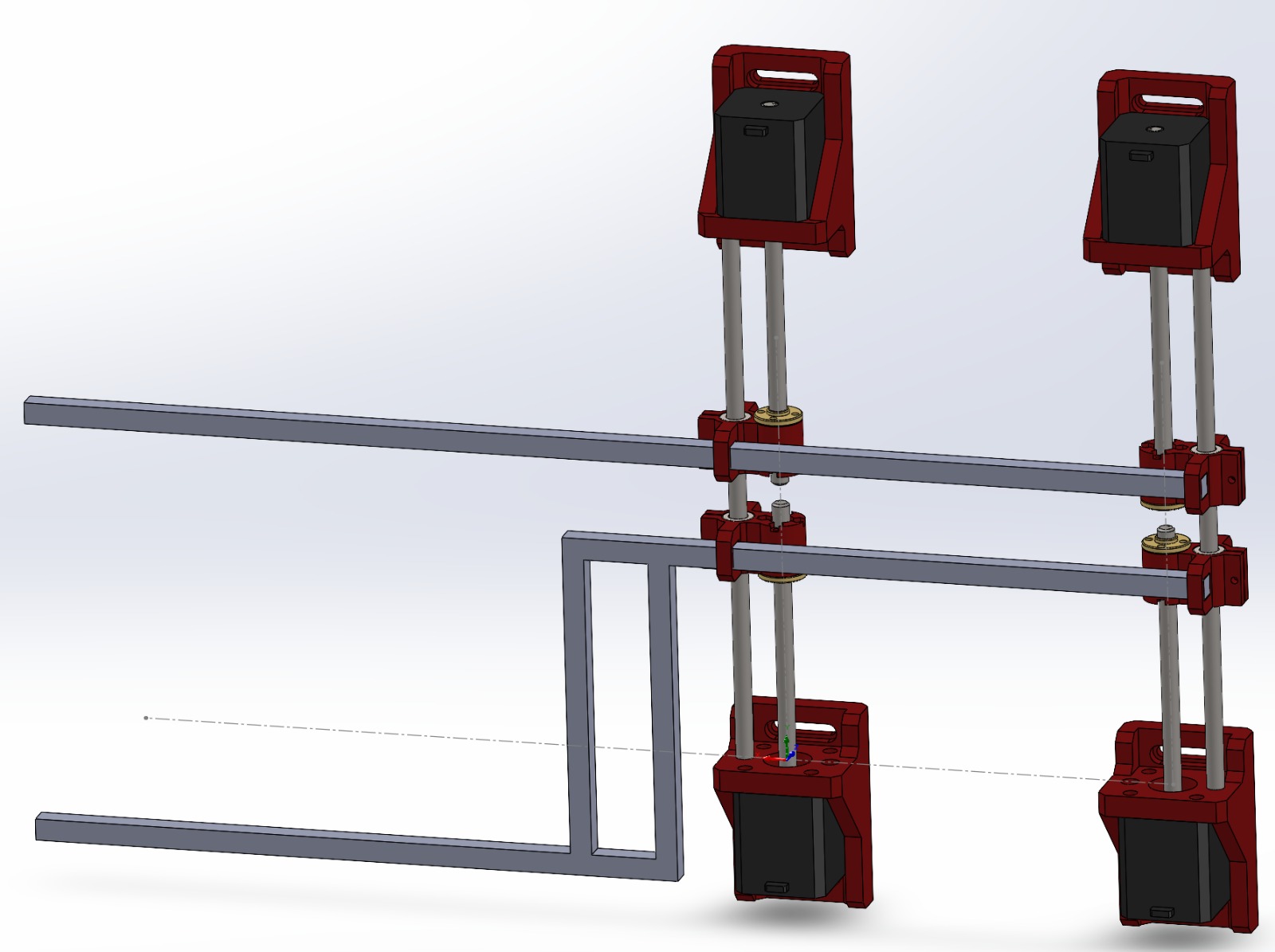

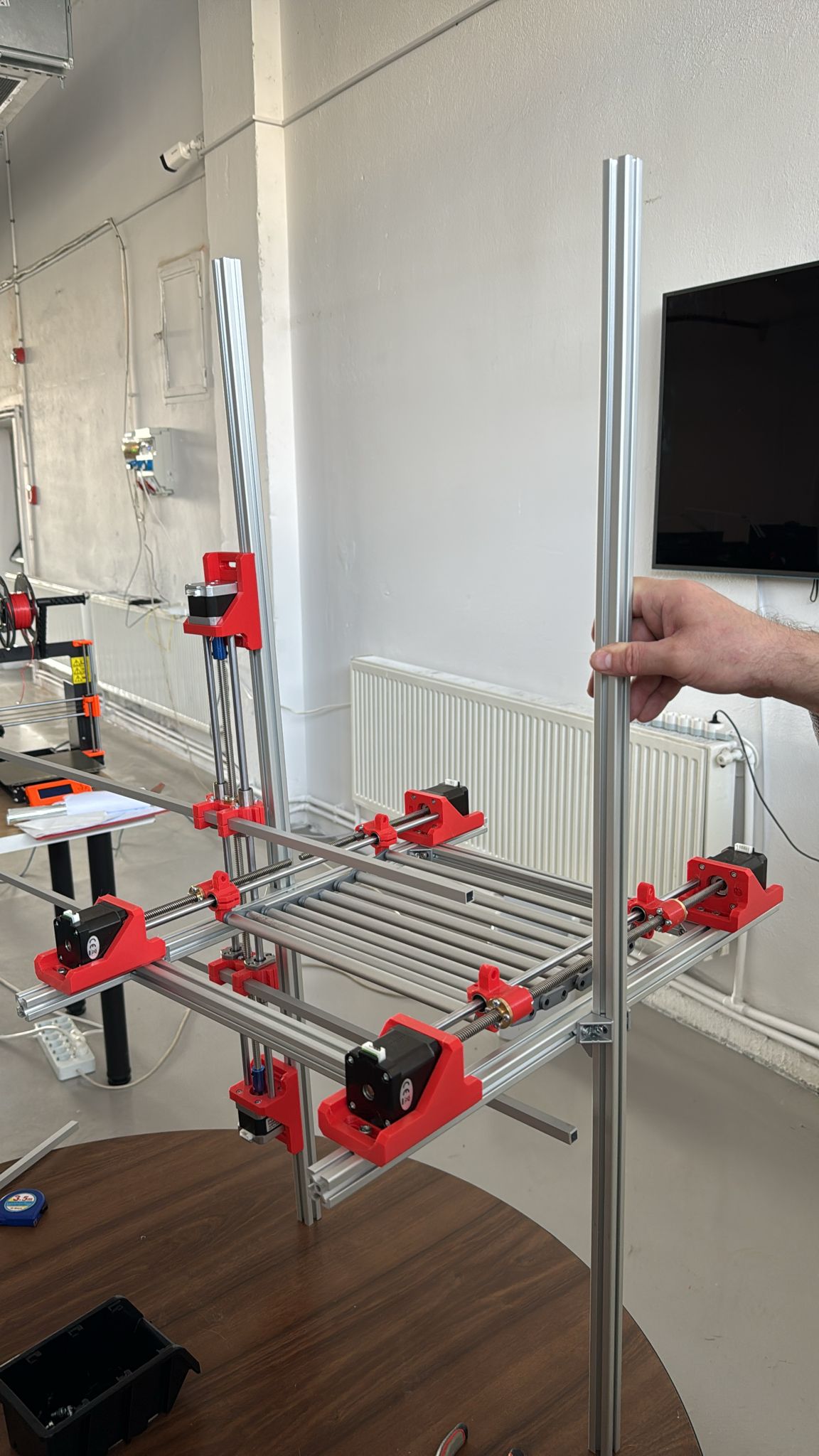

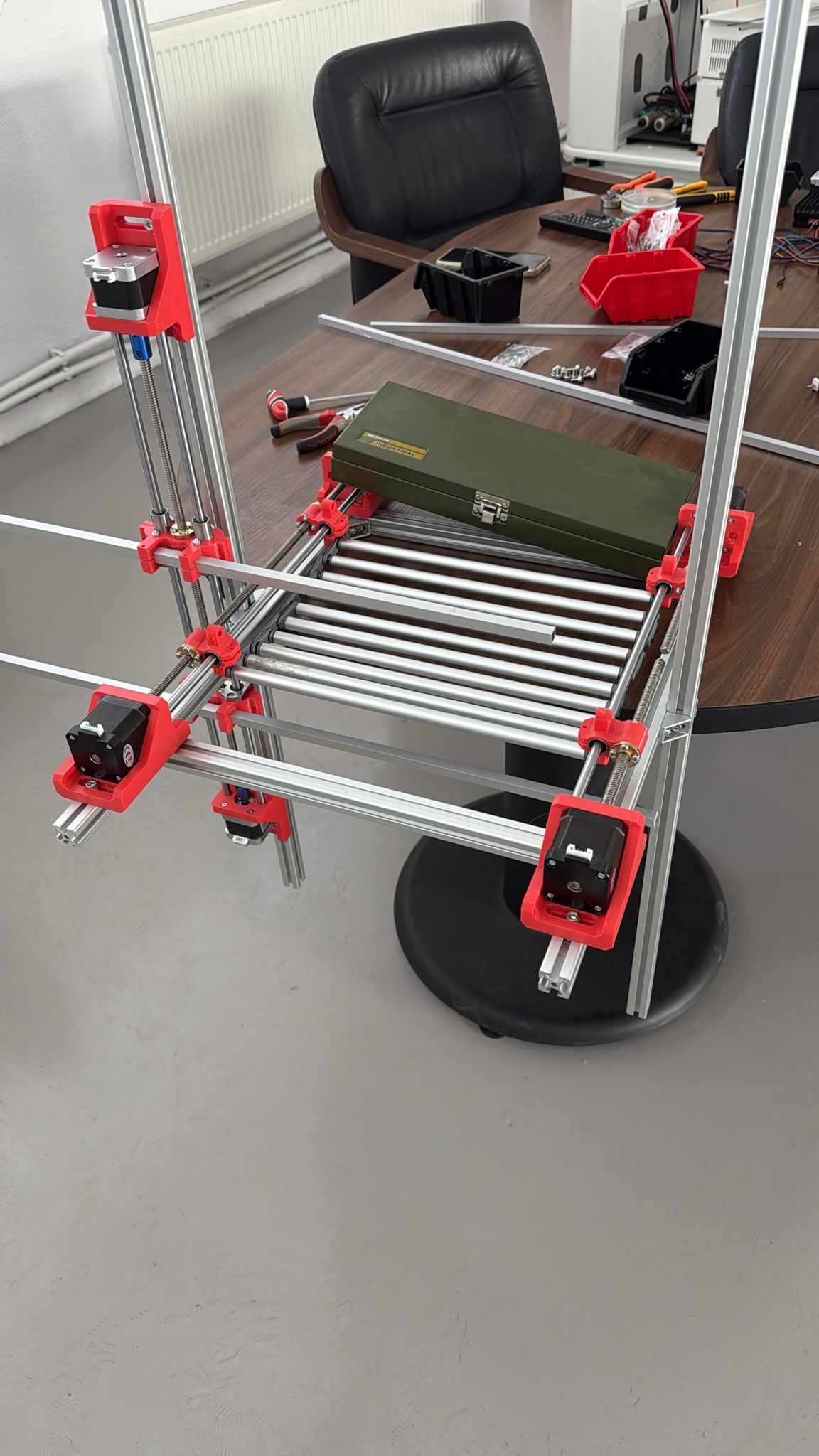

2. Wrapping

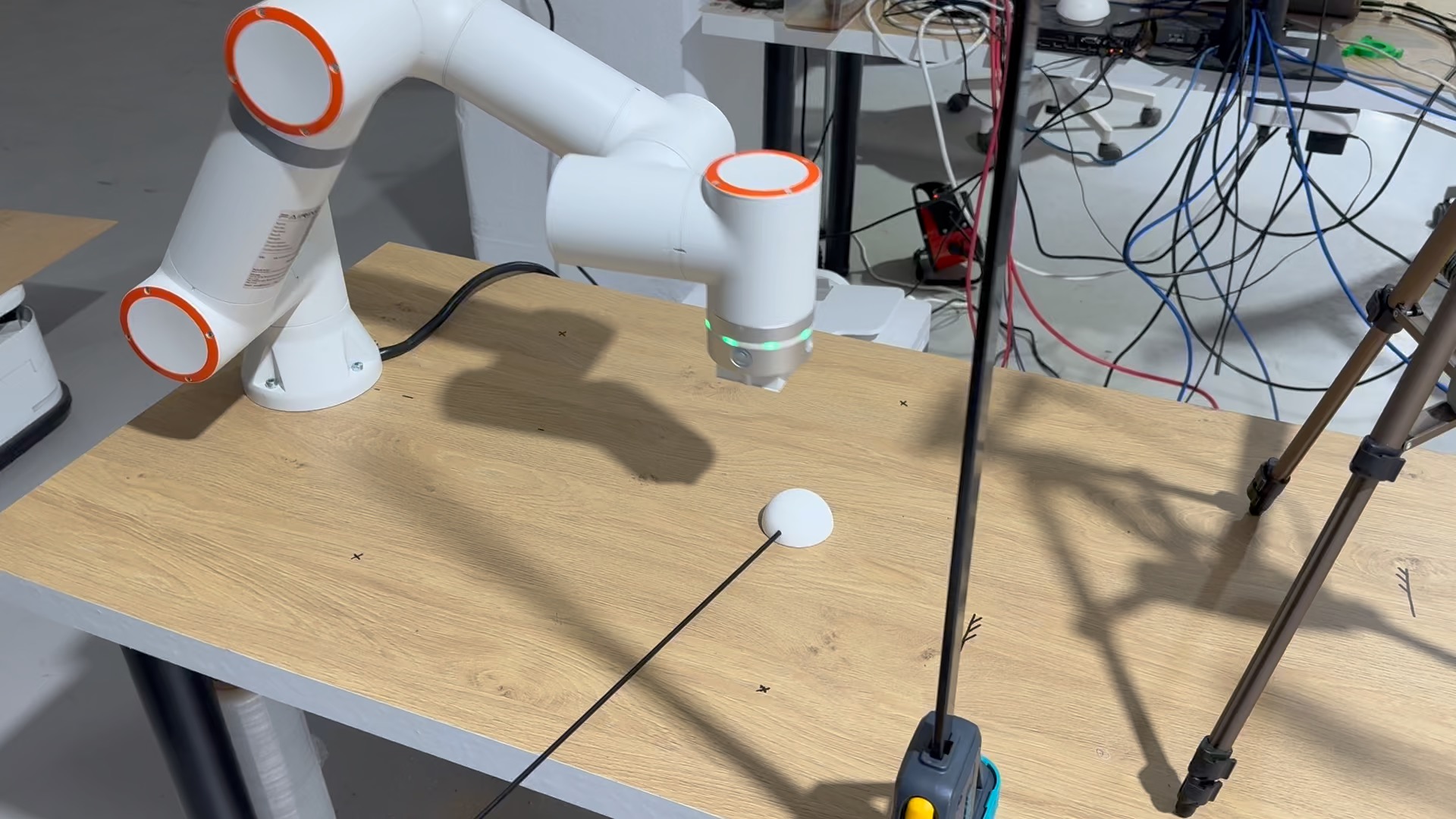

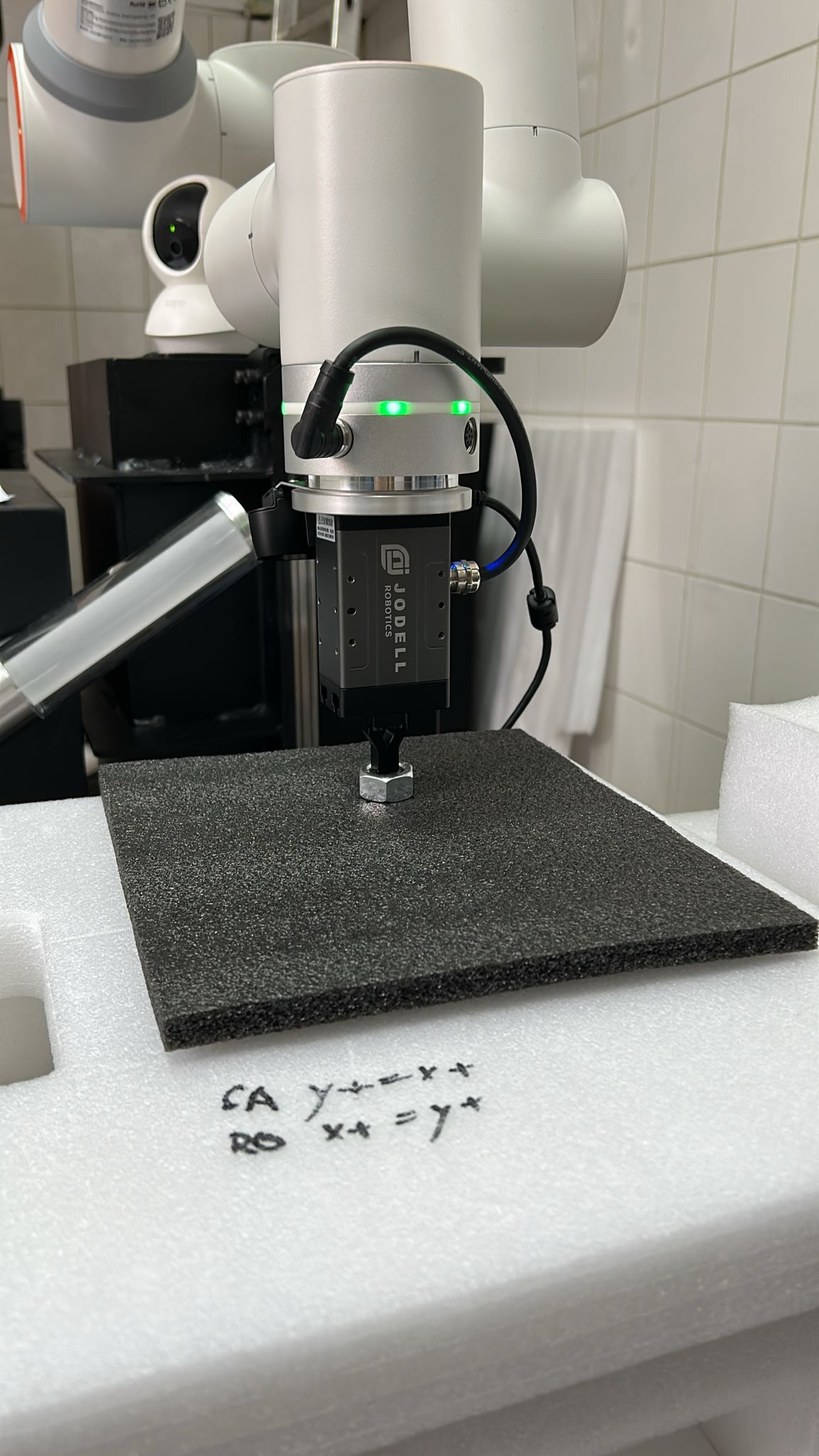

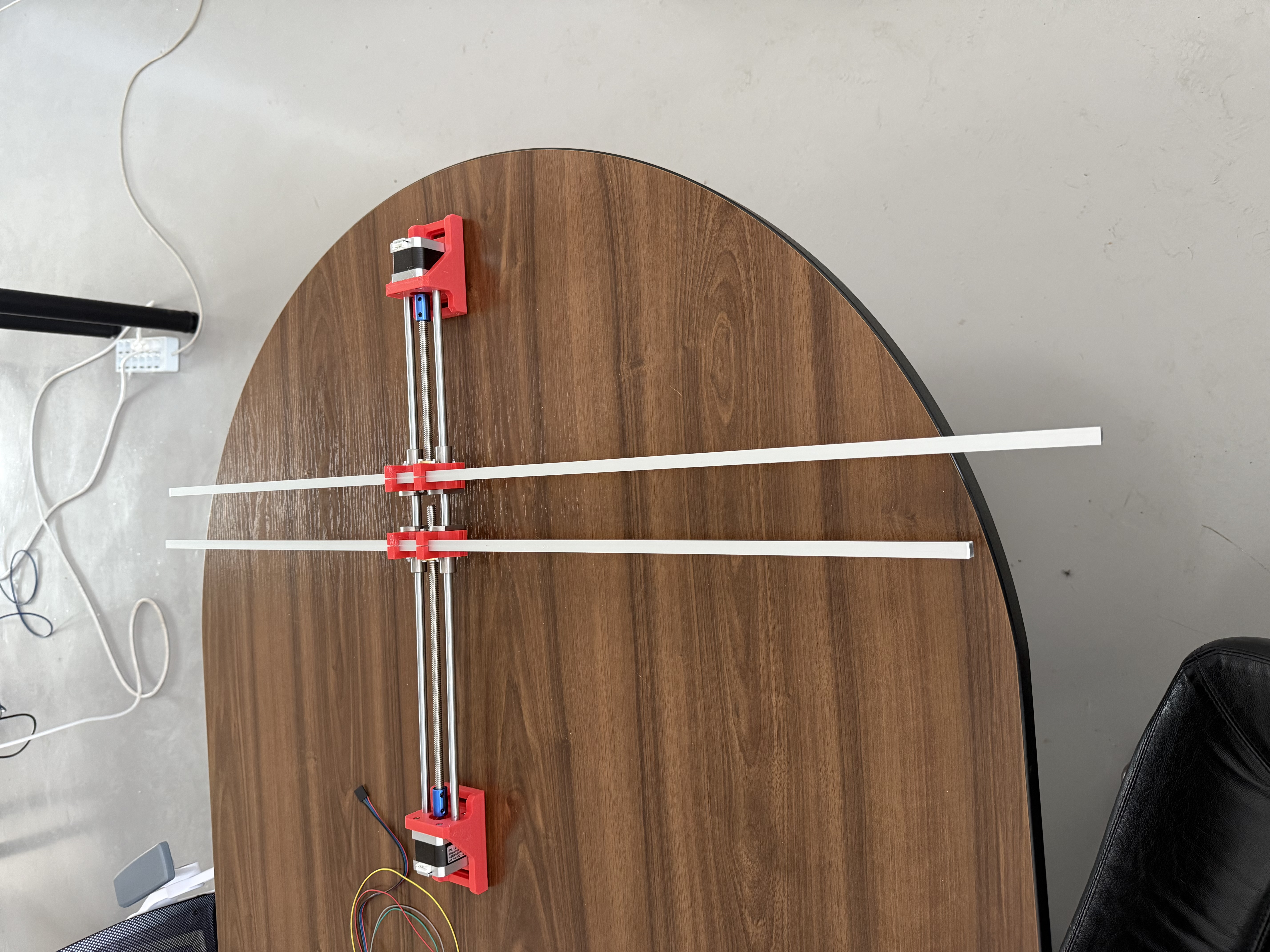

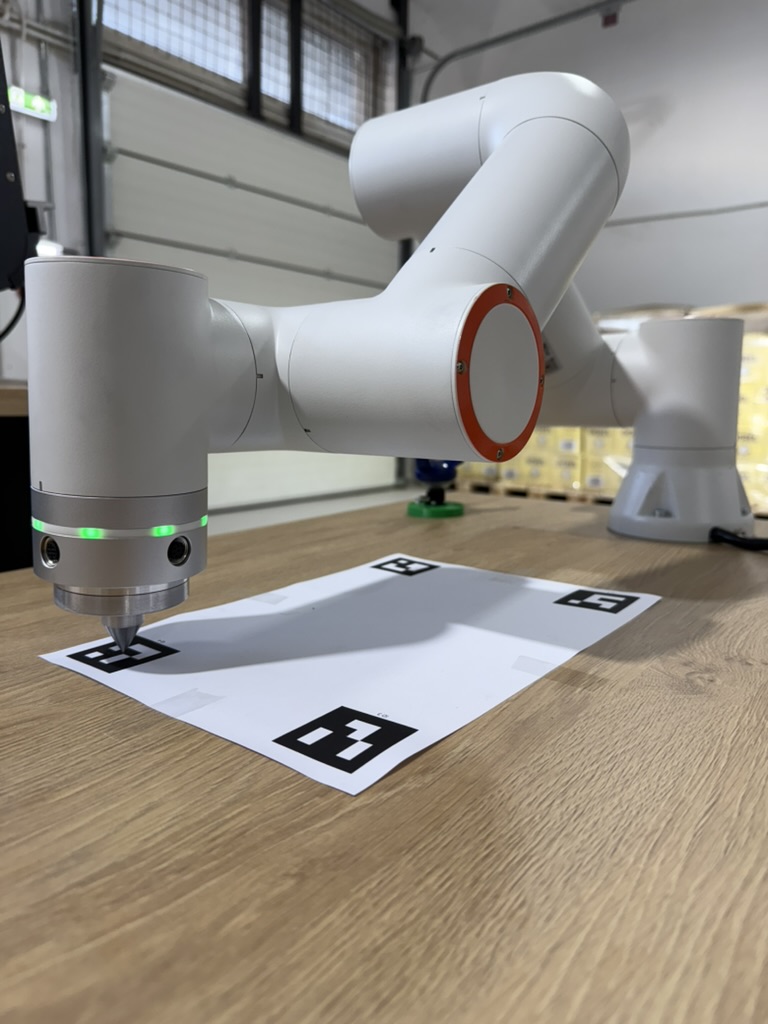

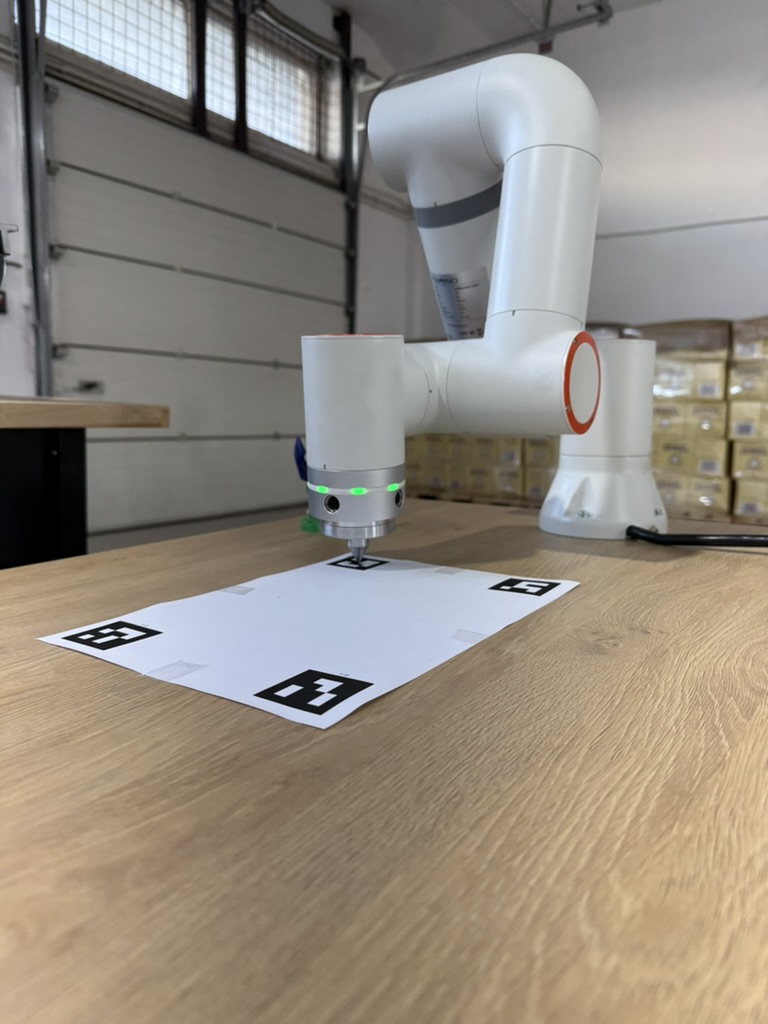

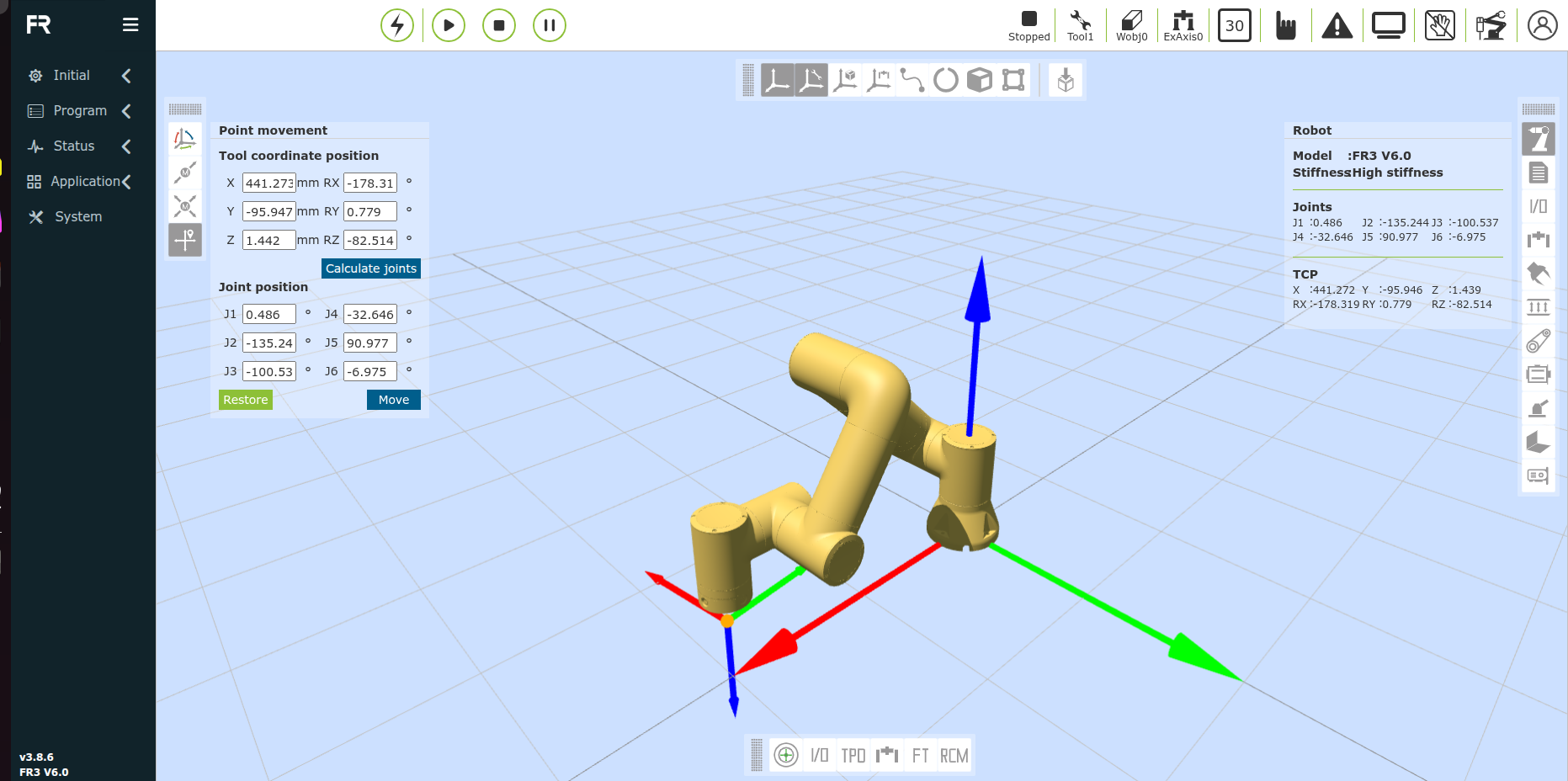

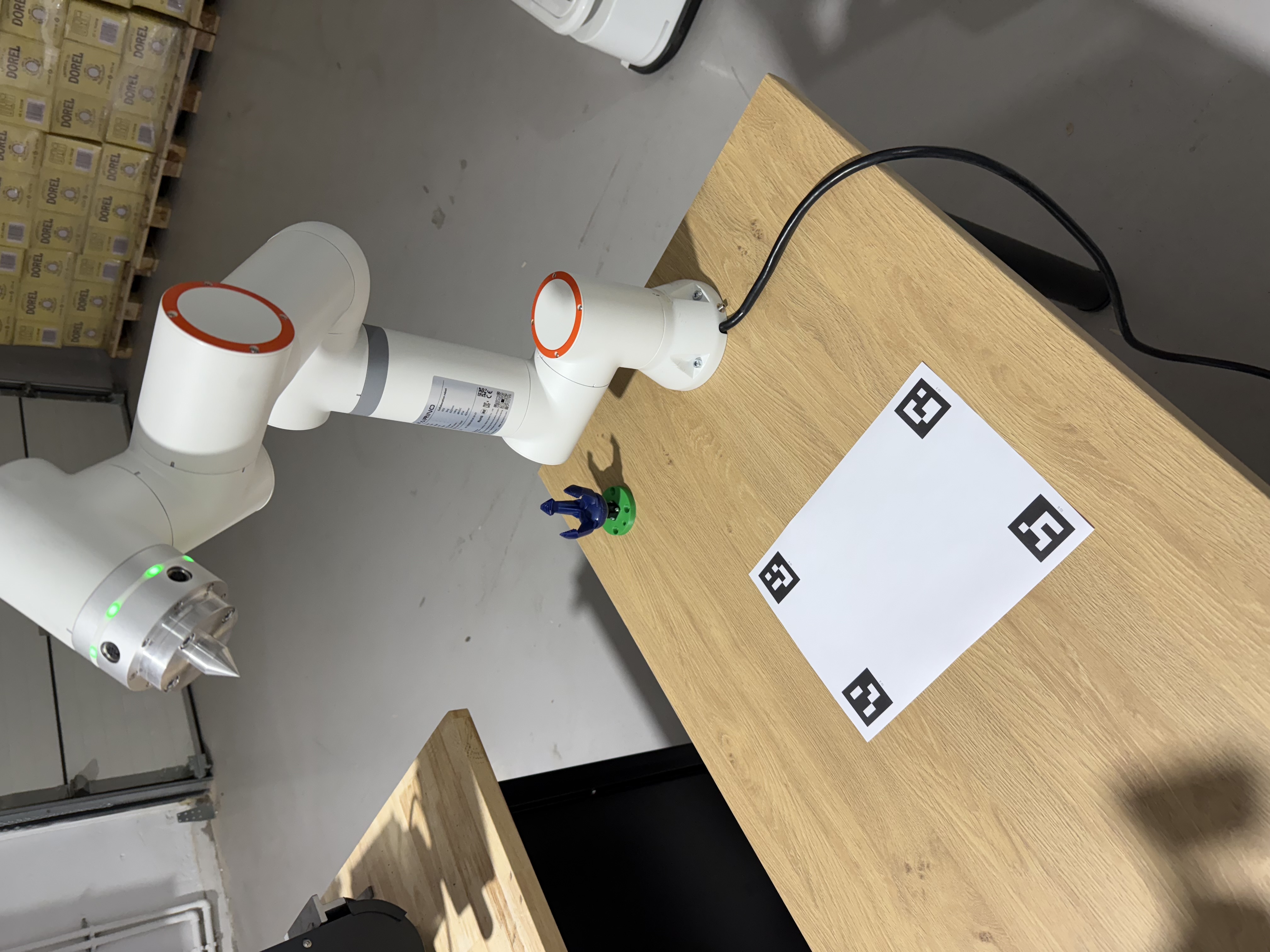

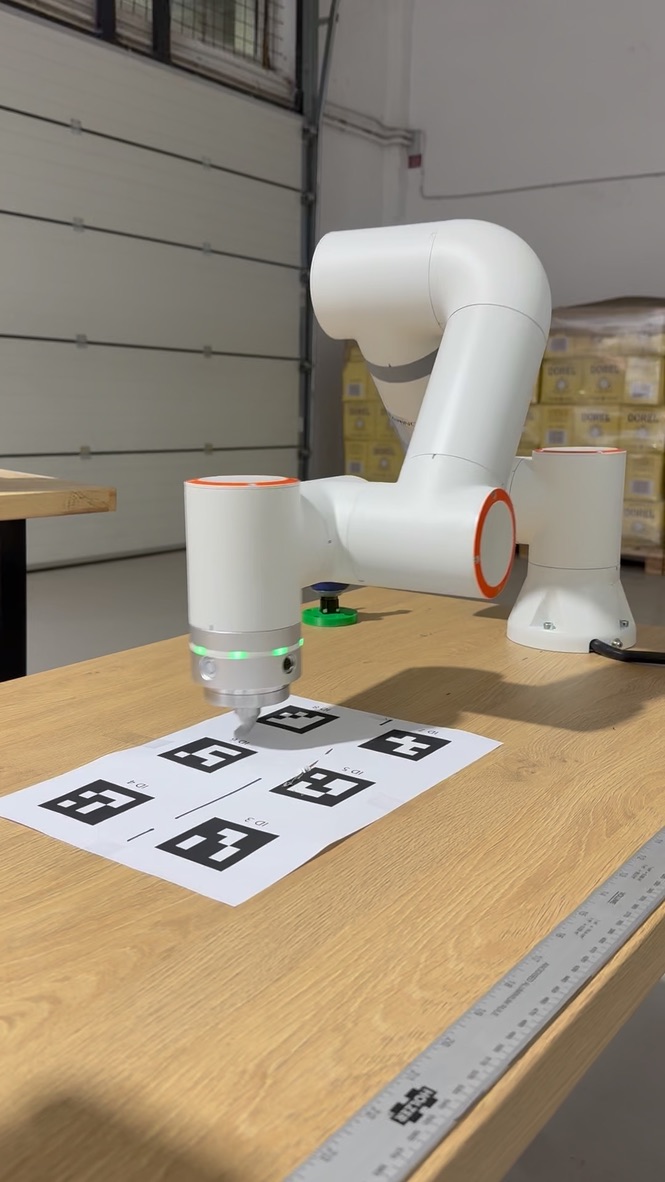

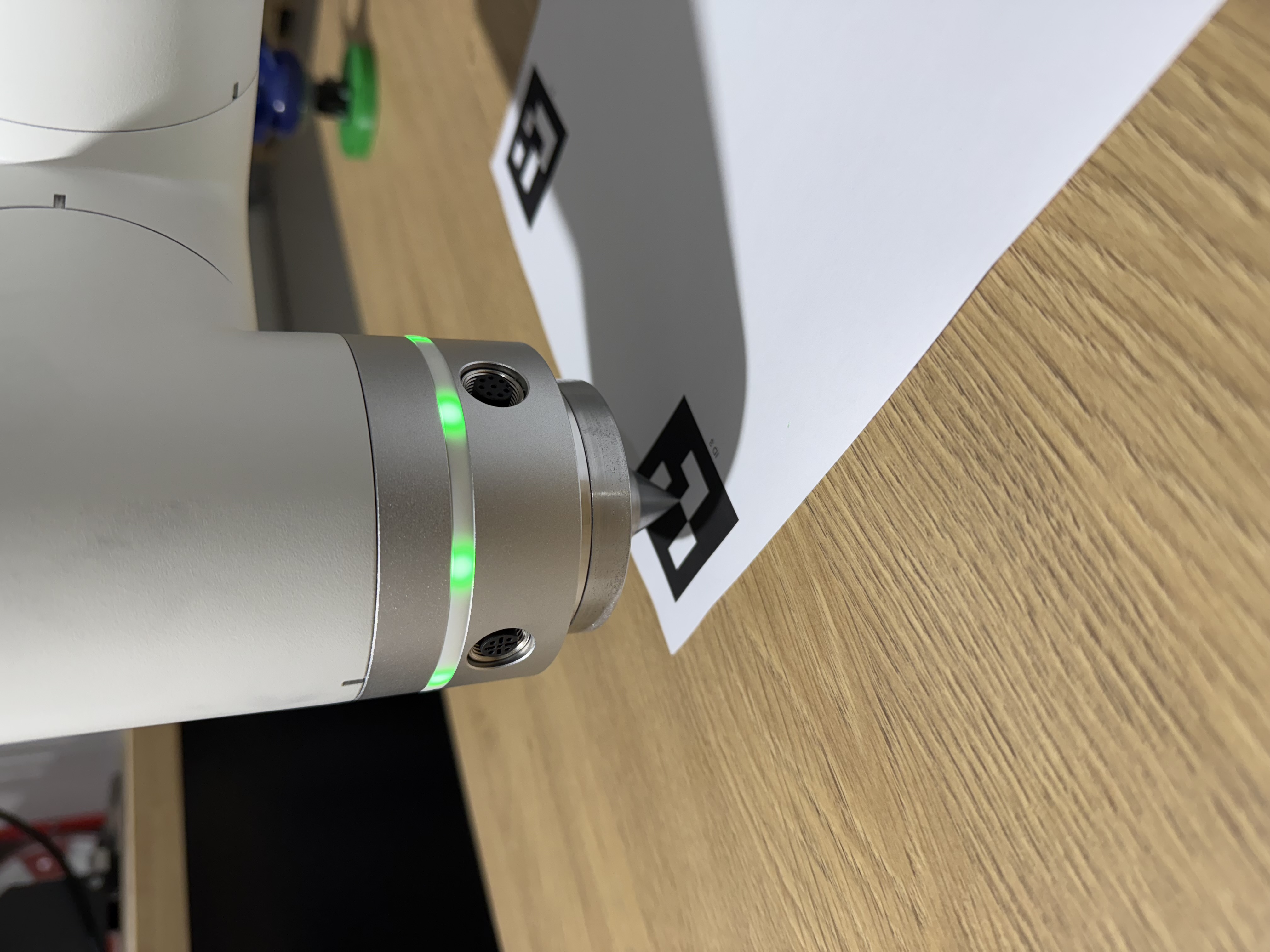

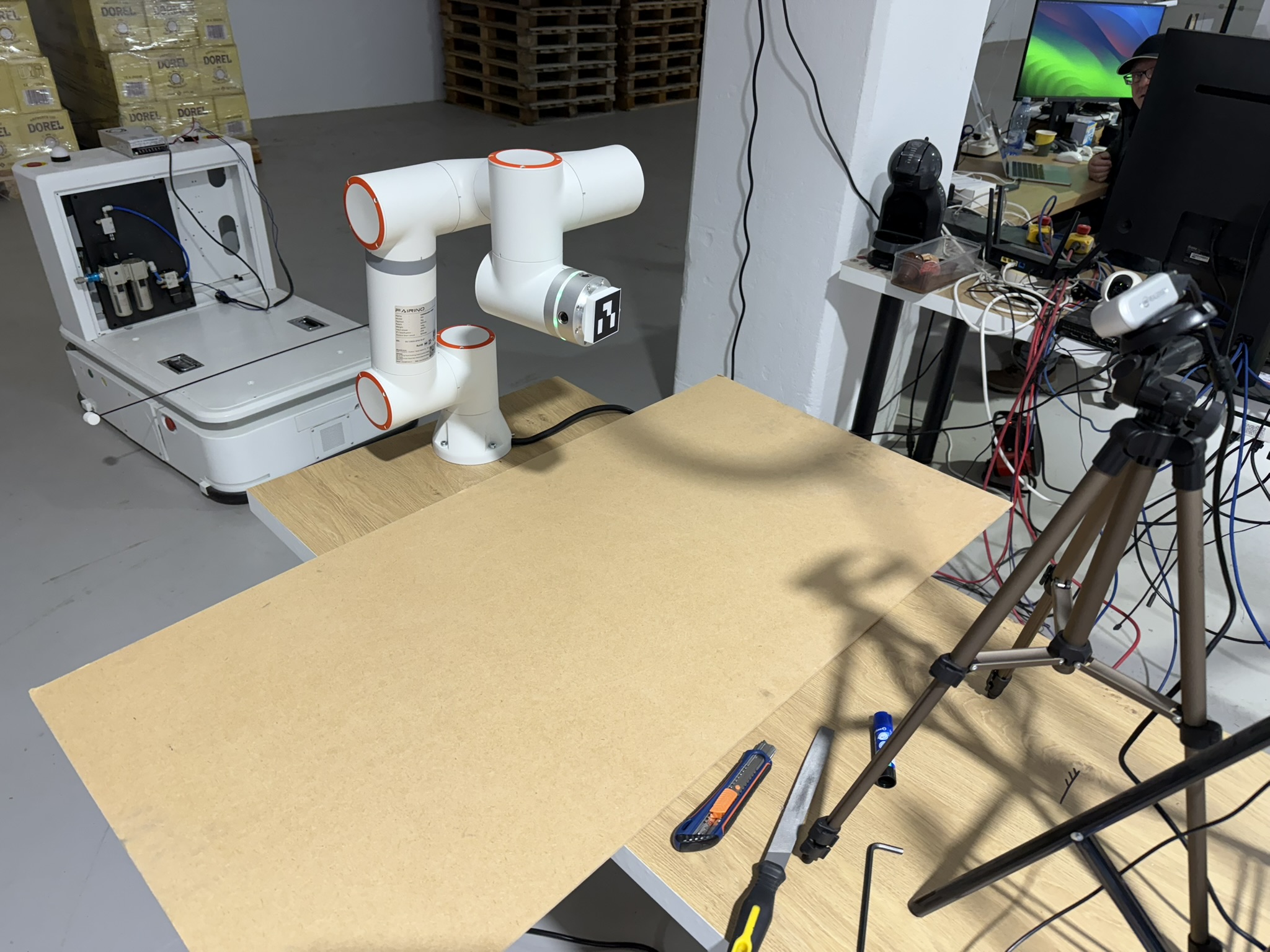

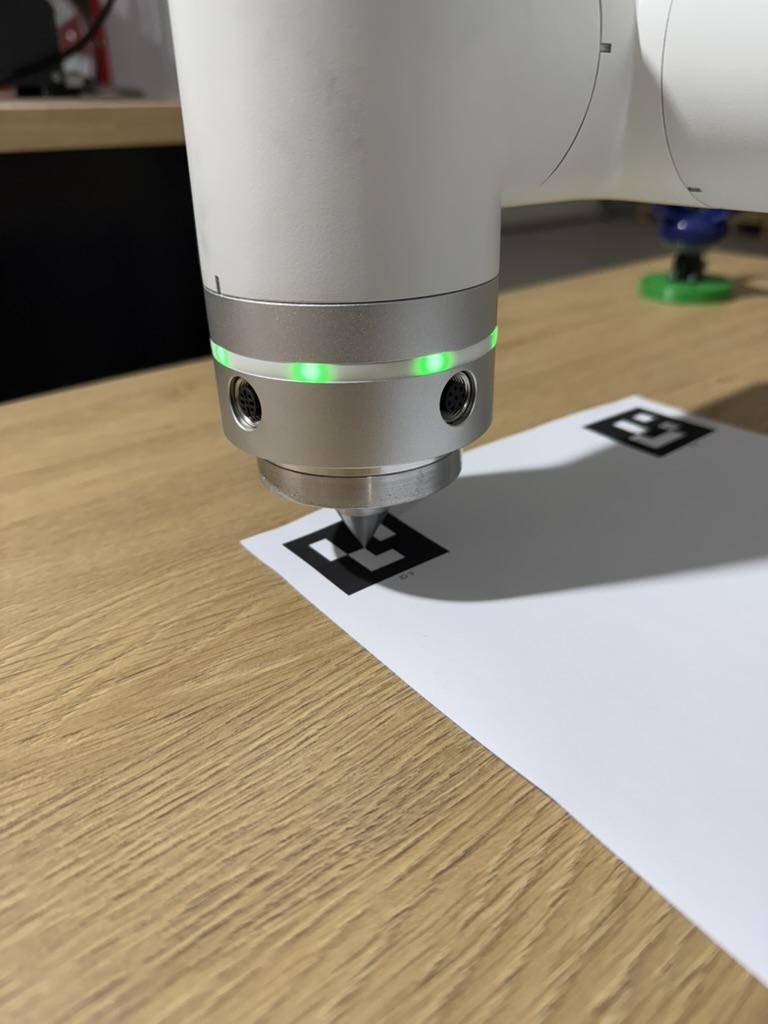

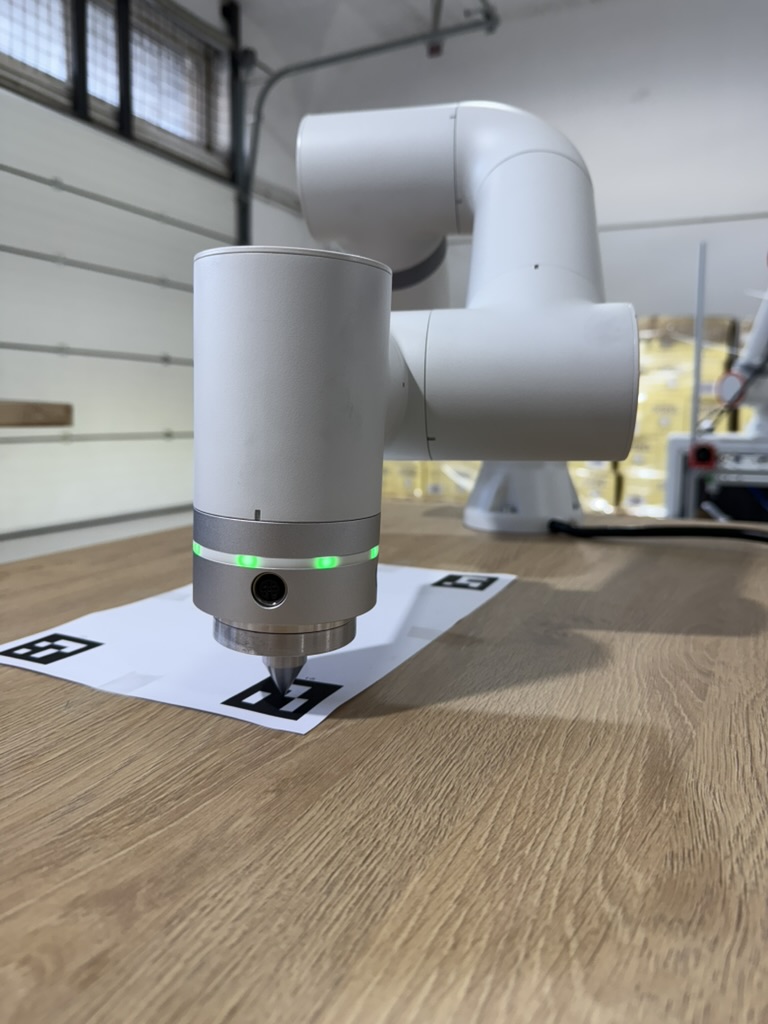

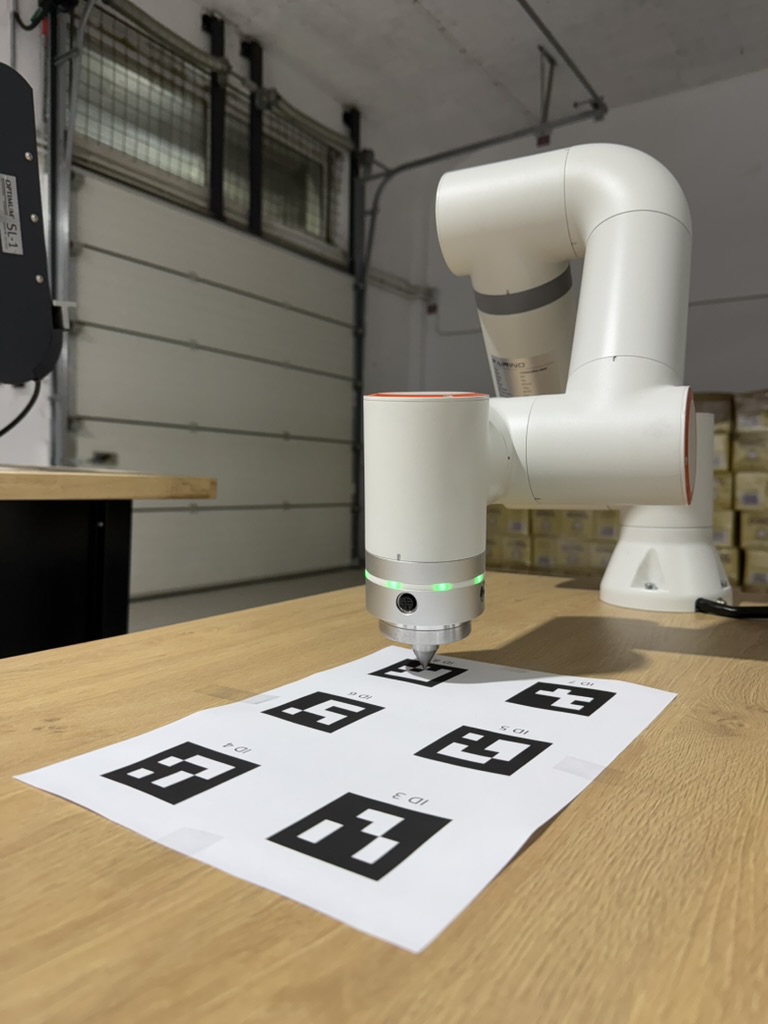

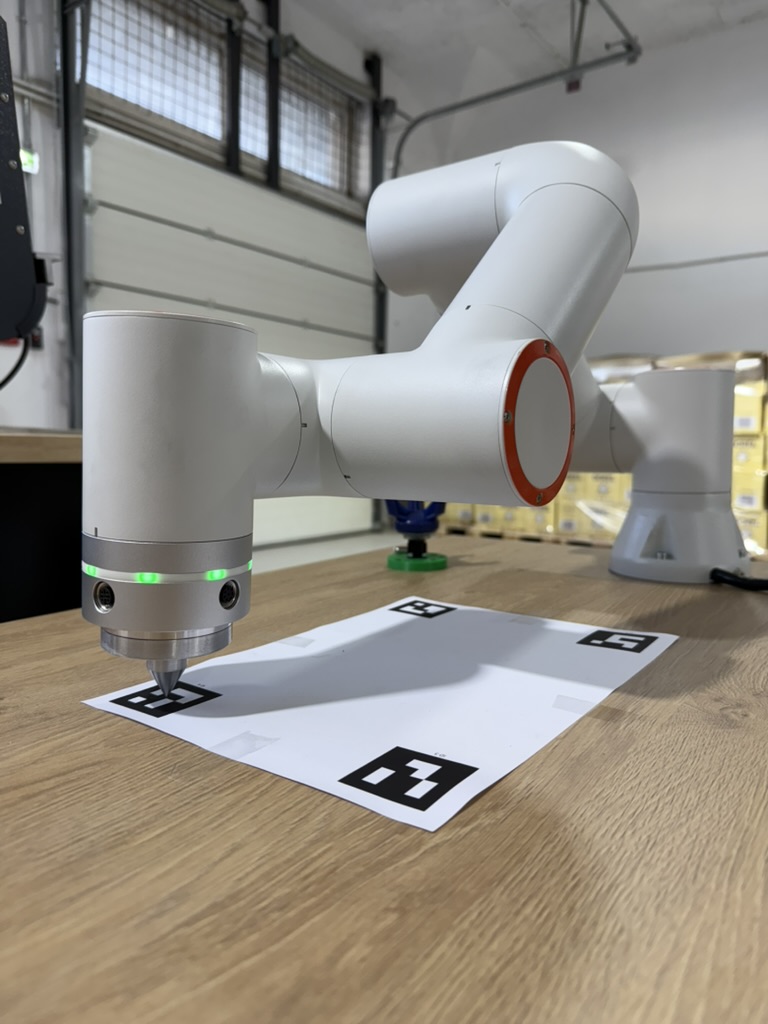

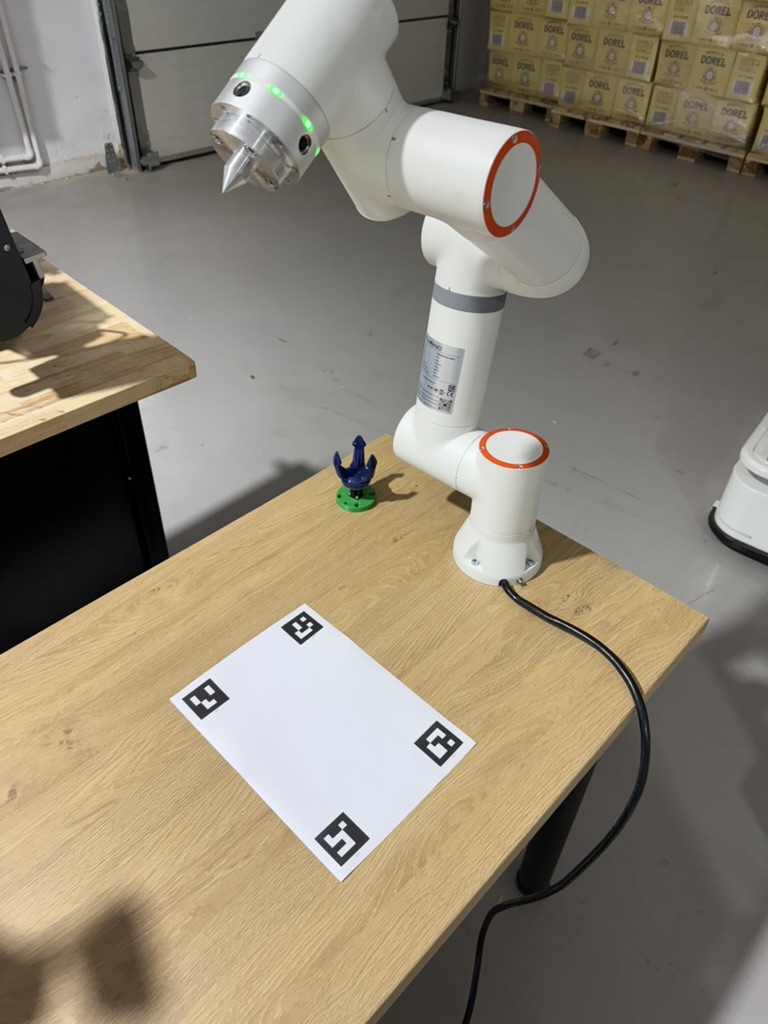

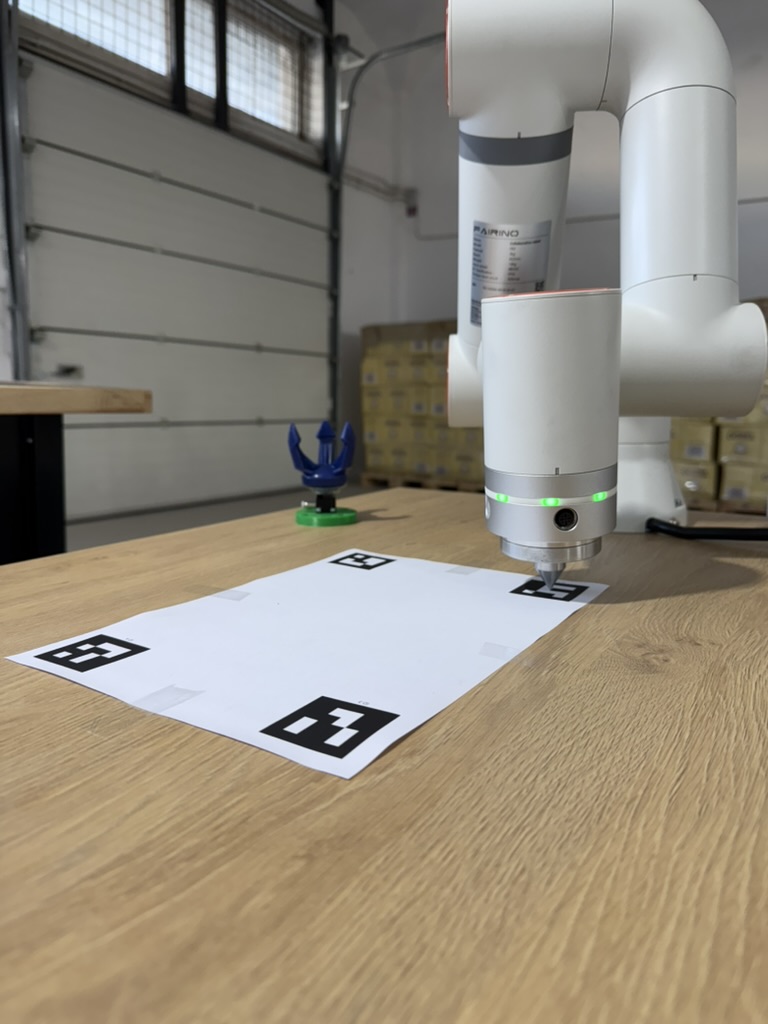

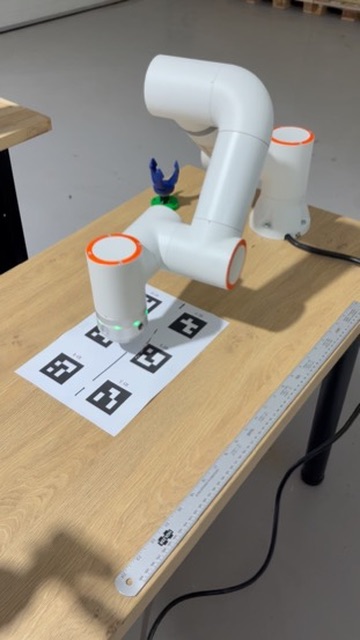

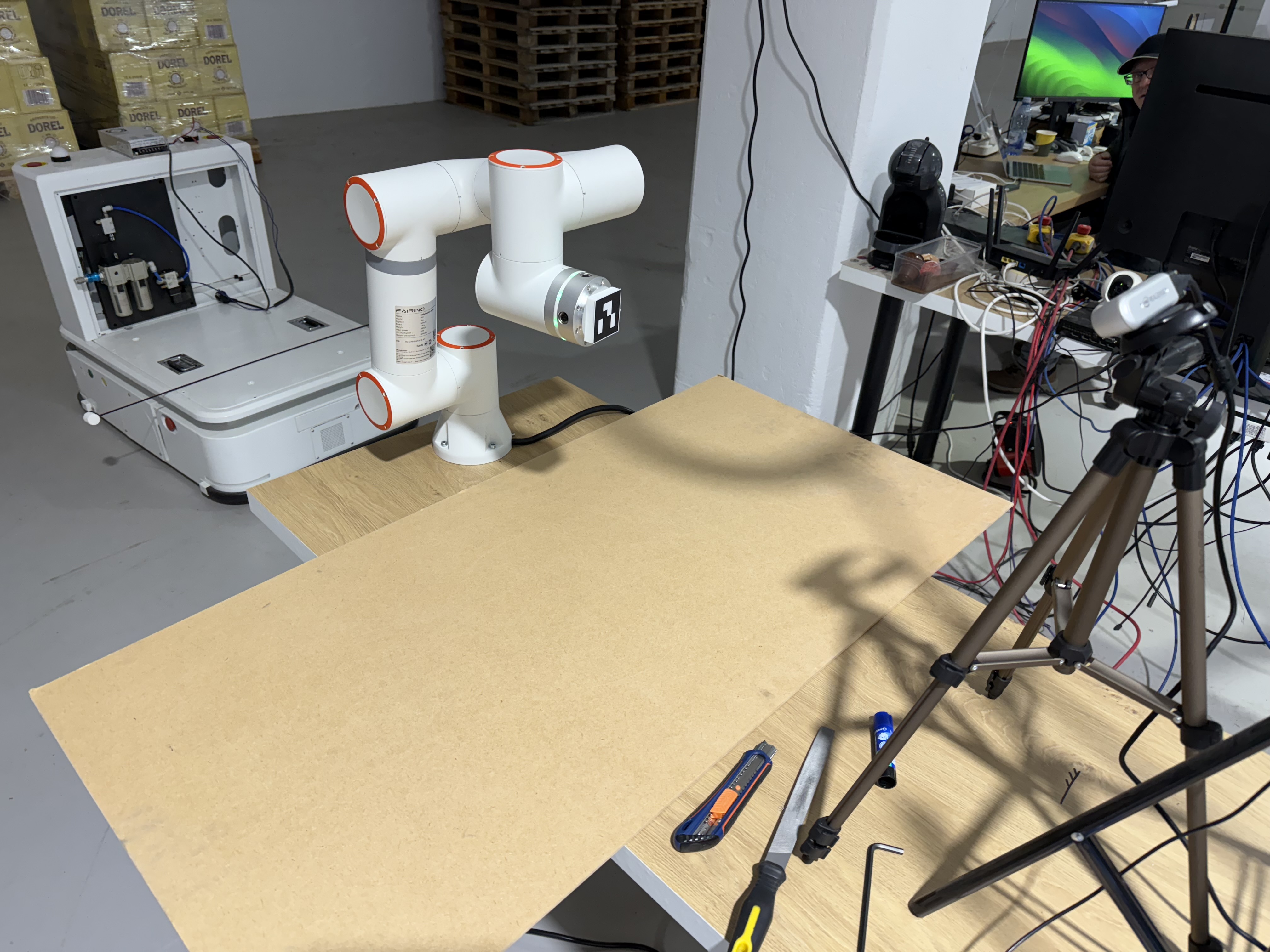

3. Calibration

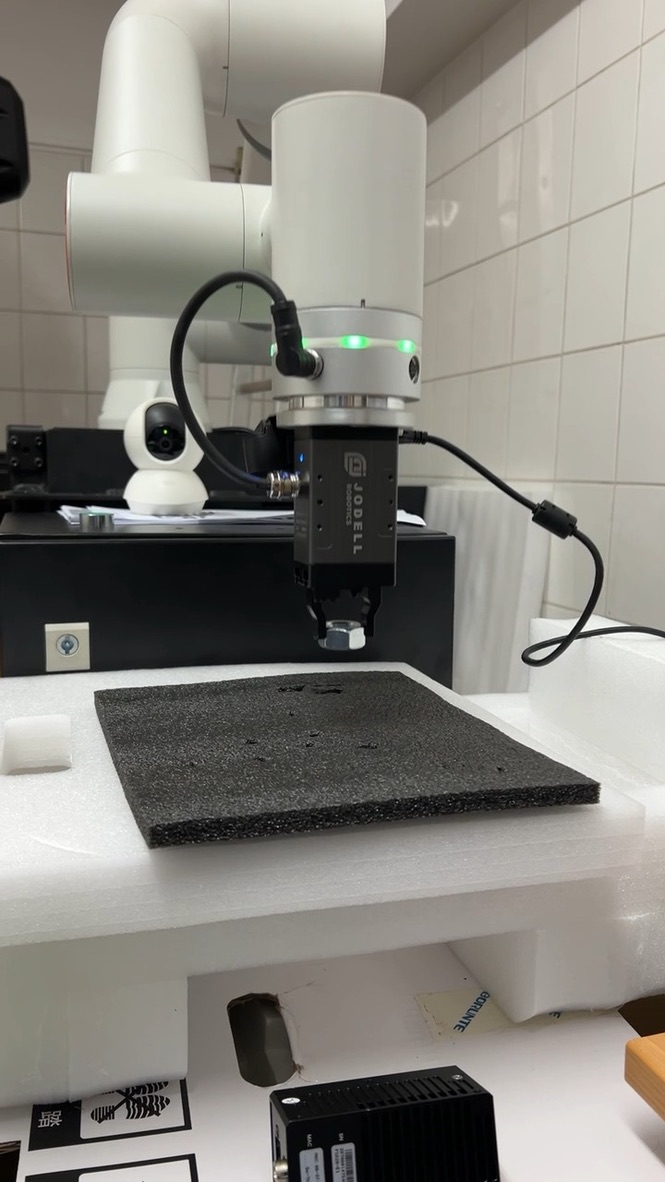

4. Thermal

🔧 What We’re Building

Ctrl-Food is both hardware and software.

🦾 Hardware

- receives ingredients

- selects & mixes vegetables

- cooks chicken/meat

- dispenses sauces

- assembles & wraps the shawarma

- packages it

- cleans itself

All 24/7, no staff, consistent output, and highly scalable.

☁️ Software (ERP SaaS)

A full cloud platform that manages:

- Order entry

- Production scheduling & execution

- Inventory & ingredient tracking

- Receiving goods and purchasing

- Shipping & delivery workflows

- Accounting integration

- Real-time analytics and chain-wide reporting

The robots are the execution layer.

The ERP is the brain.

Together they form the world’s first fully autonomous restaurant operating system.

🔥 Why This Matters

Fast-food is one of the most labor-intensive industries.

A typical shop spends $105k/year on staff.

We eliminate that entirely.

Our first partner — Shaormitza.ro (~$1M/month revenue) — is hosting pilot modules and committed to expanding to 40+ locations once validated.

This gives us:

- real production environments

- real data

- real revenue paths

- real scalability

🛠 Progress

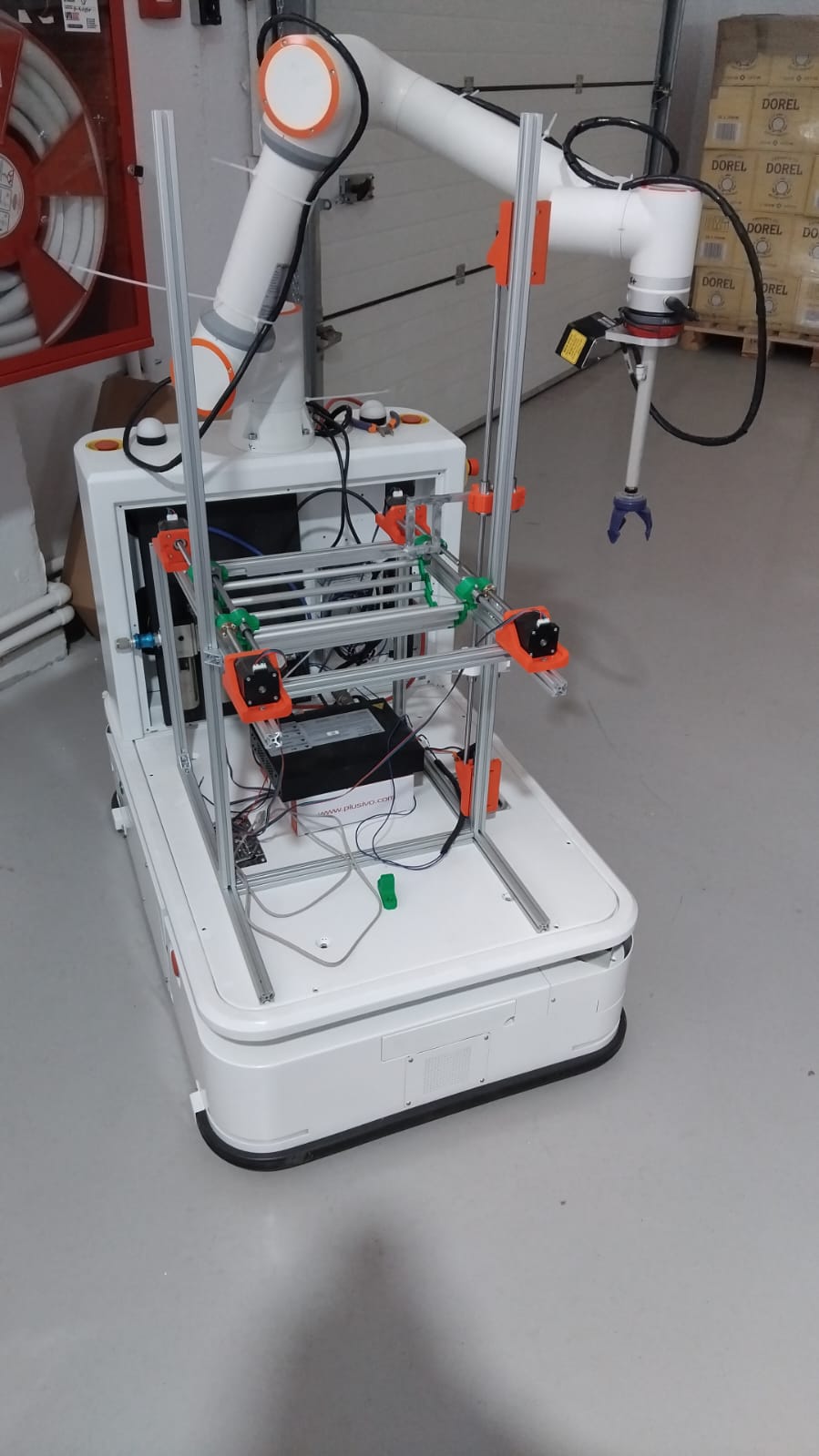

Robotics & Manipulation

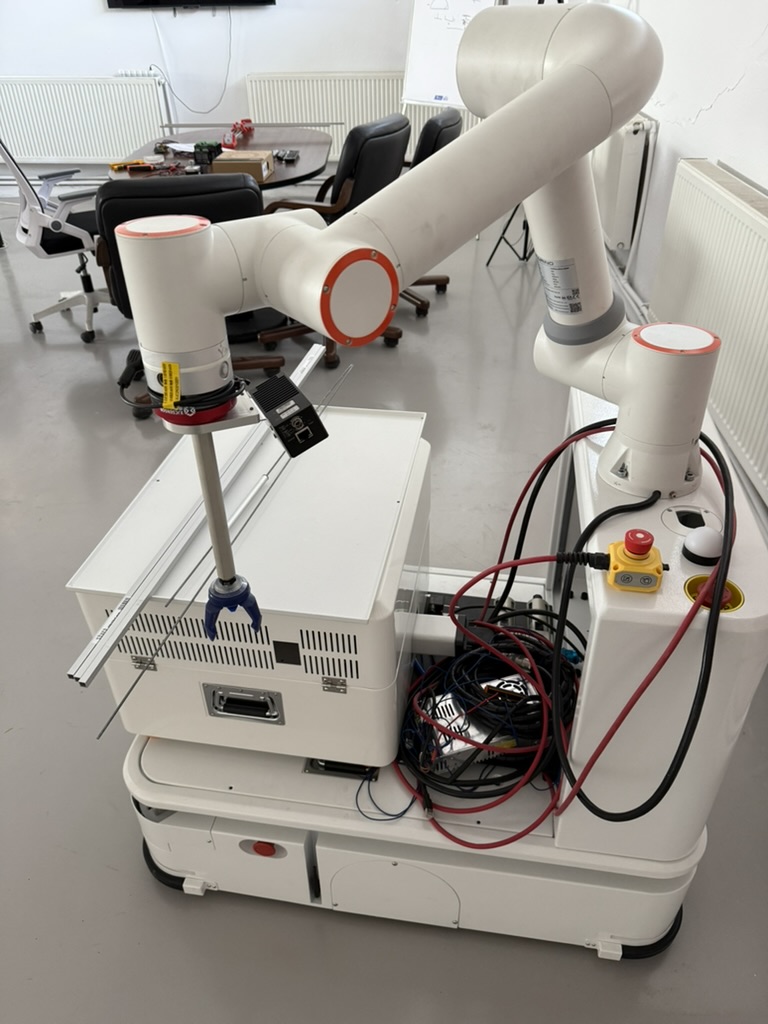

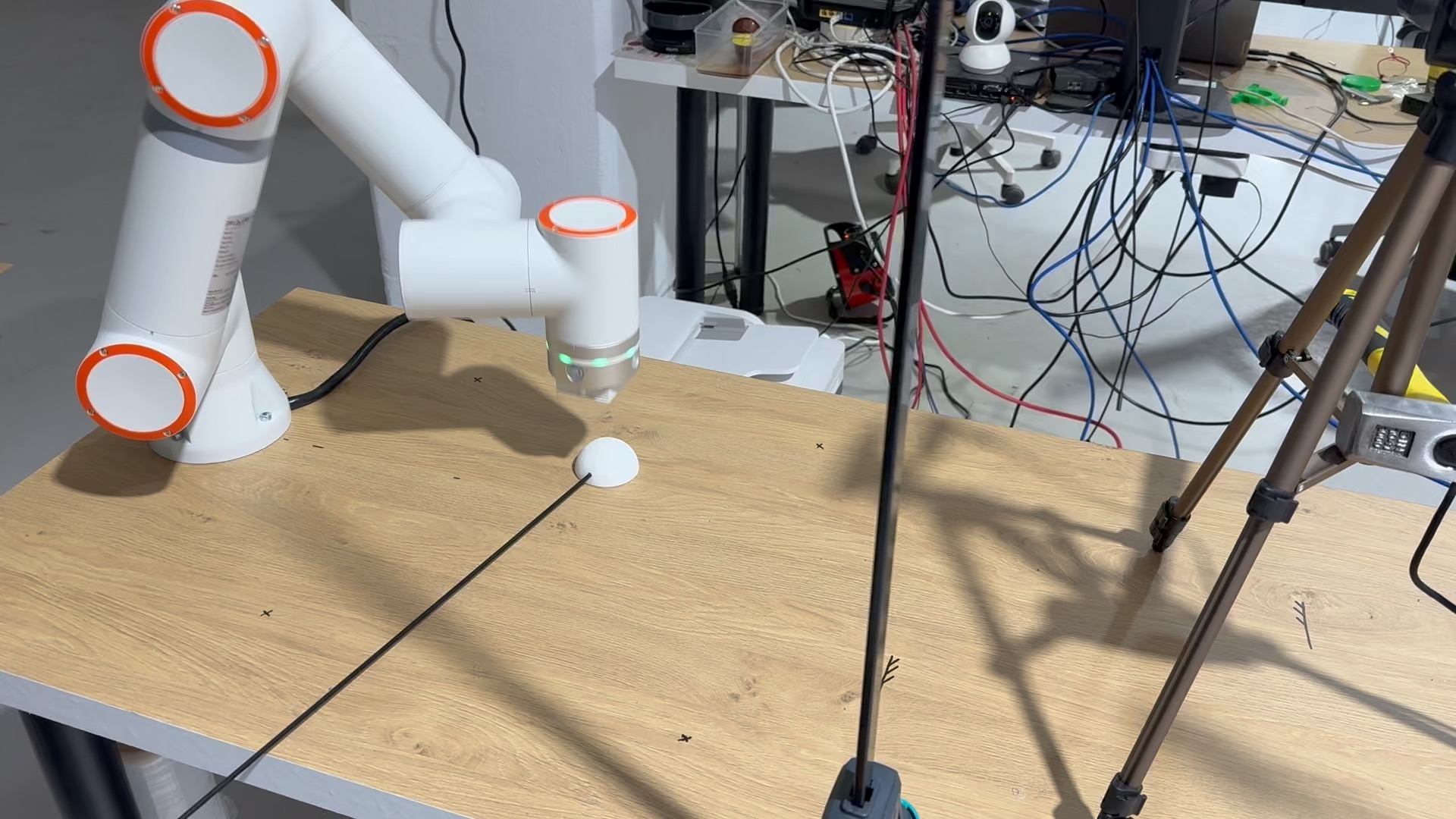

- FR5 cobot performing stable pick-and-place on real vegetables

- Evaluated a Borunte 100 kg industrial robot for automated receiving, pallet movement, and heavy-load workflows

- Tested a Borunte SCARA robot for ultra-fast pick-and-place cycles and high-throughput ingredient handling

- Custom EOATs: pneumatic, electromechanical, and soft grippers with interchangeable fingers and force sensors

- Designed and fabricated custom fixtures: 3D-printed prototypes and steel/aluminum flanges manufactured in China

- Depth-sensing evaluation: tested Orbbec, Percipio, and Intel RealSense; selected Intel RealSense D421f for precision and reliability

- Built a depth-based vegetable-handling pipeline with consistent grasp accuracy

- Optimized the geometry and arrangement of vegetable pots for fastest robotic access and high throughput

🤖 Vision & AI

- YOLO (v8, v12) for object detection

- Depth-based picking using Orbbec, Percipio, Intel RealSense

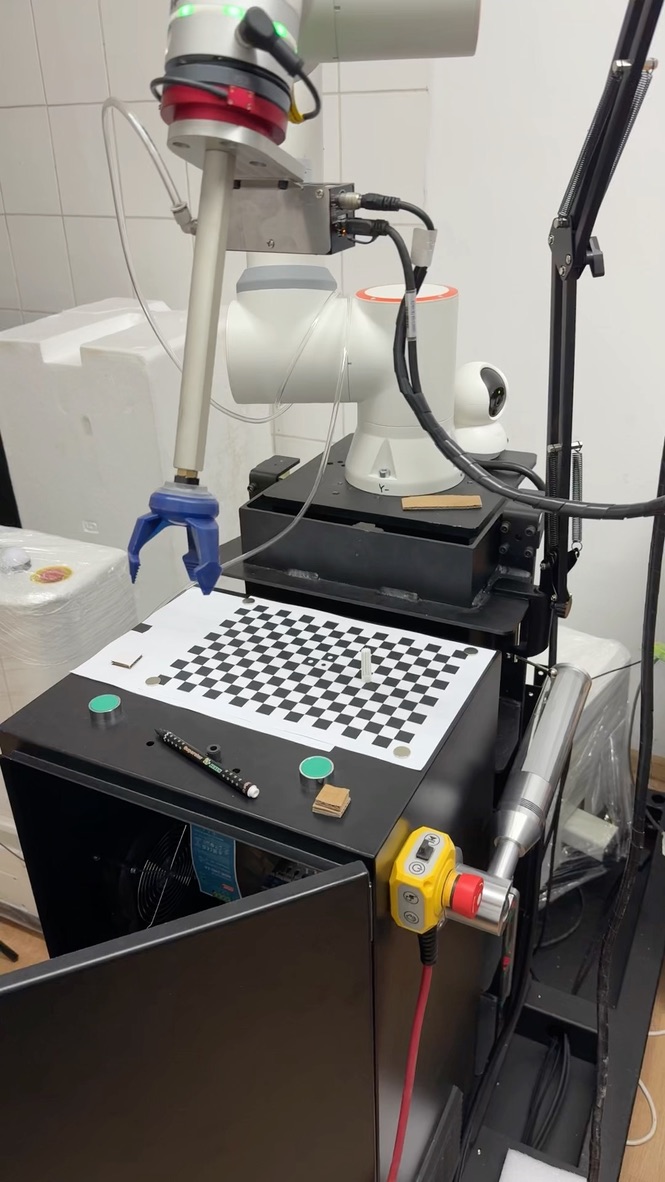

- Calibrated multi-camera setup with ArUco & chessboard workflows

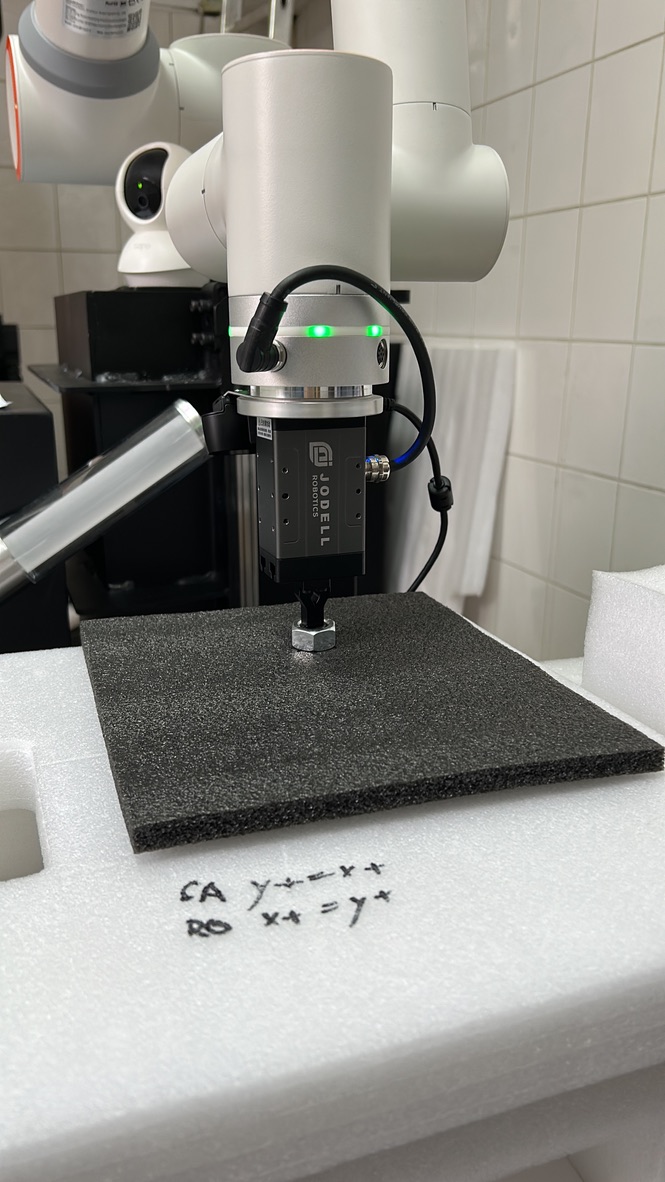

- Evaluated radiometric thermal sensing using the Leopard Lepton module (TELEDYNE FLIR Lepton® 3.5) for real-time surface temperature monitoring during cooking

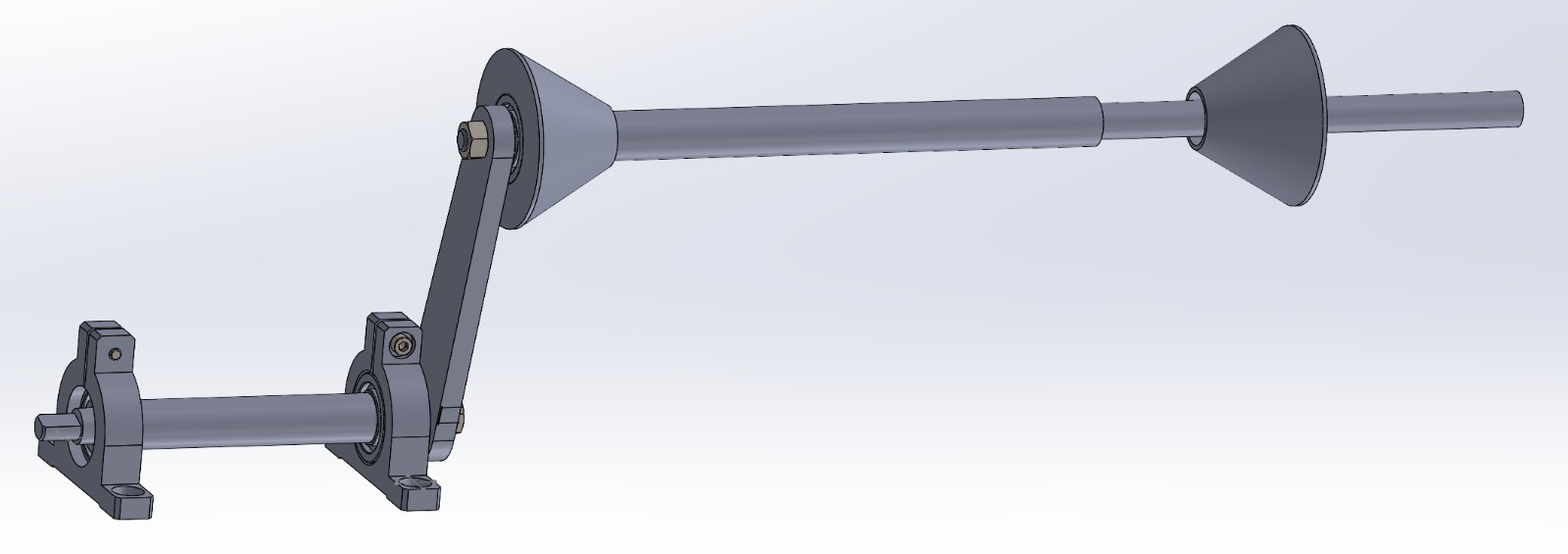

- Developed an automatic camera-to-robot calibration routine: the robot moves an ArUco marker through ~100 known poses, logging robot and camera data to compute and validate the transformation matrix

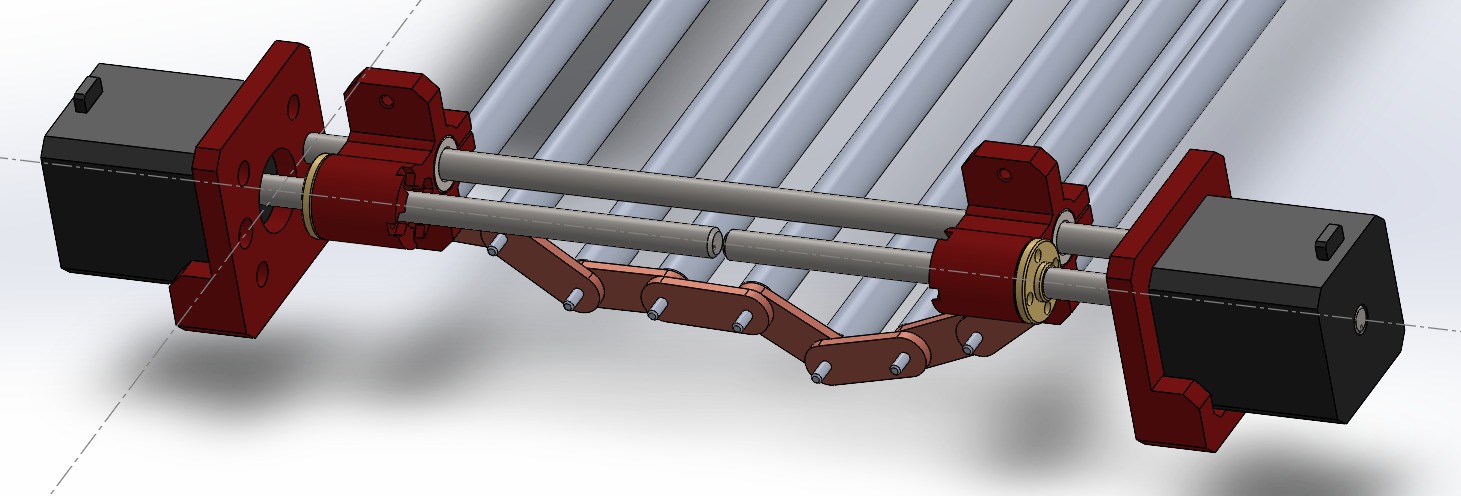

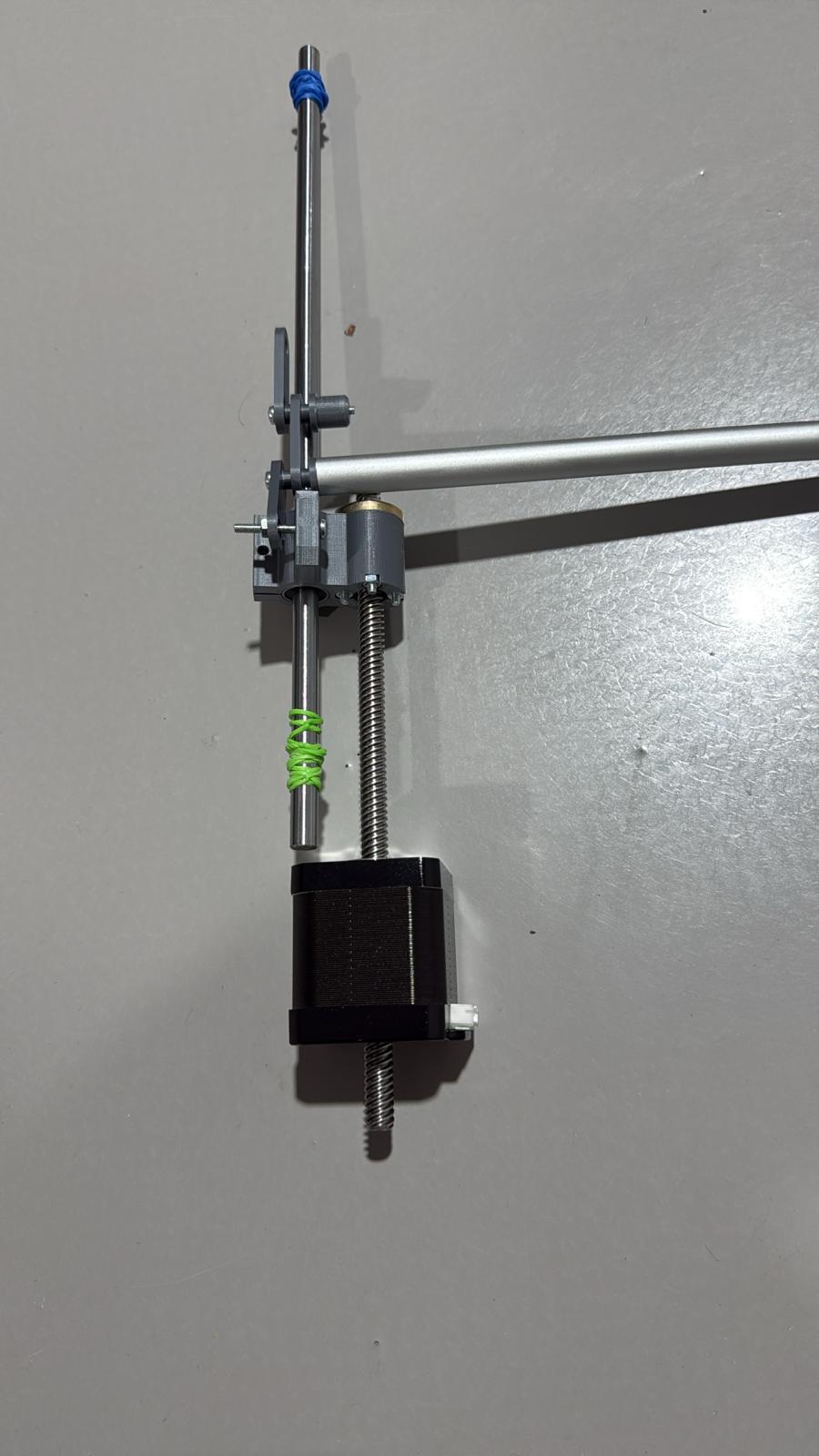

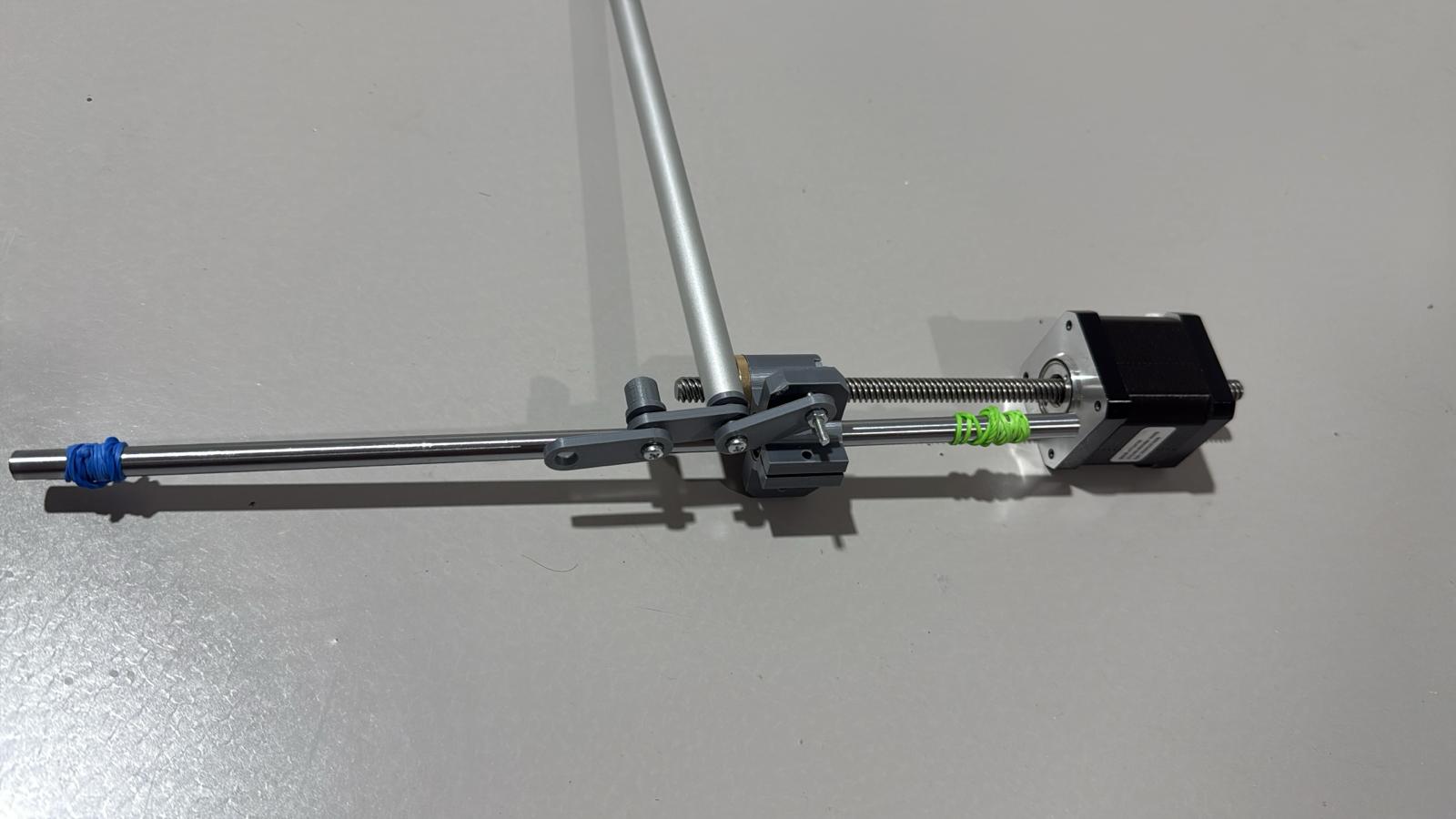

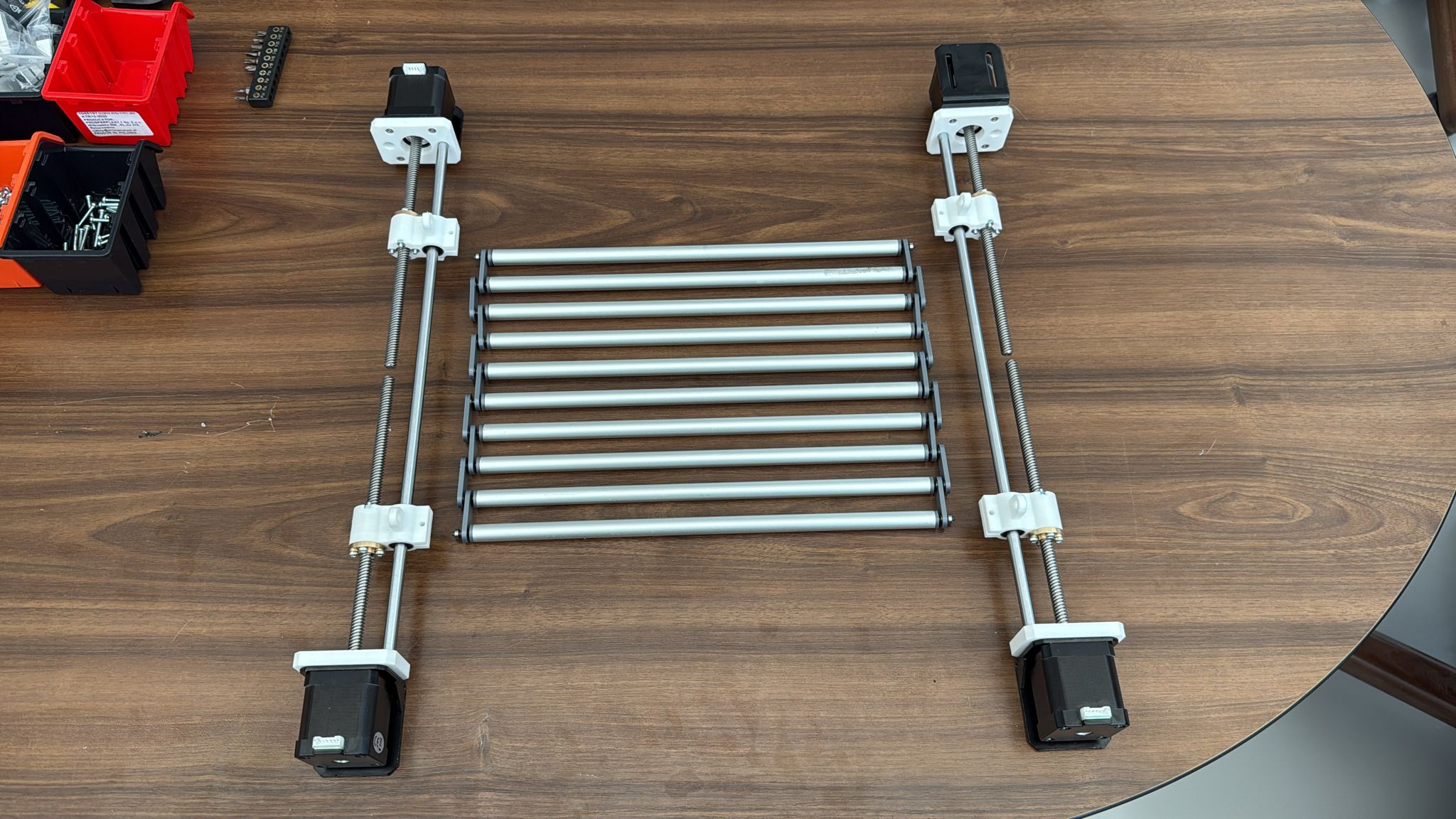

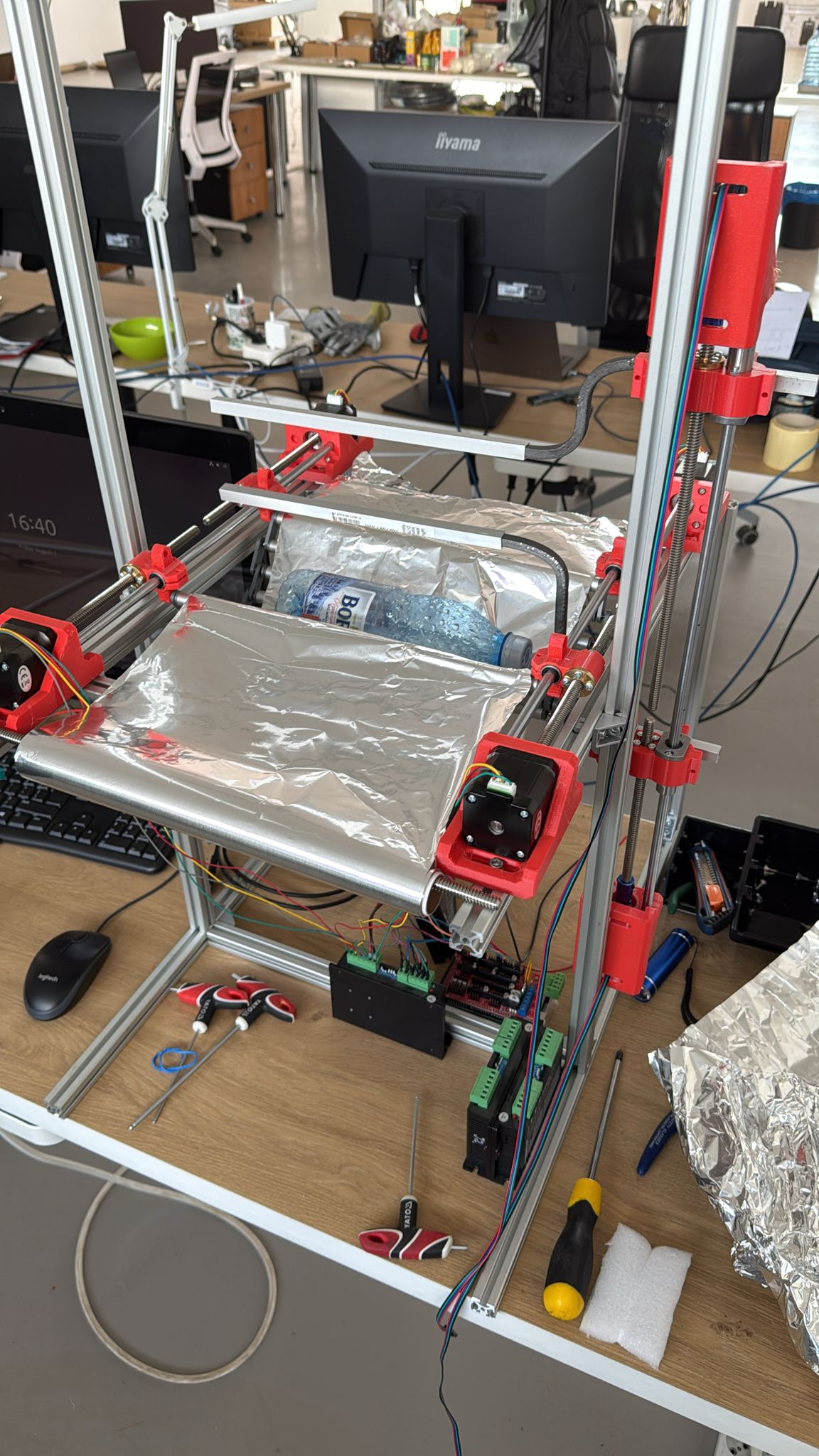

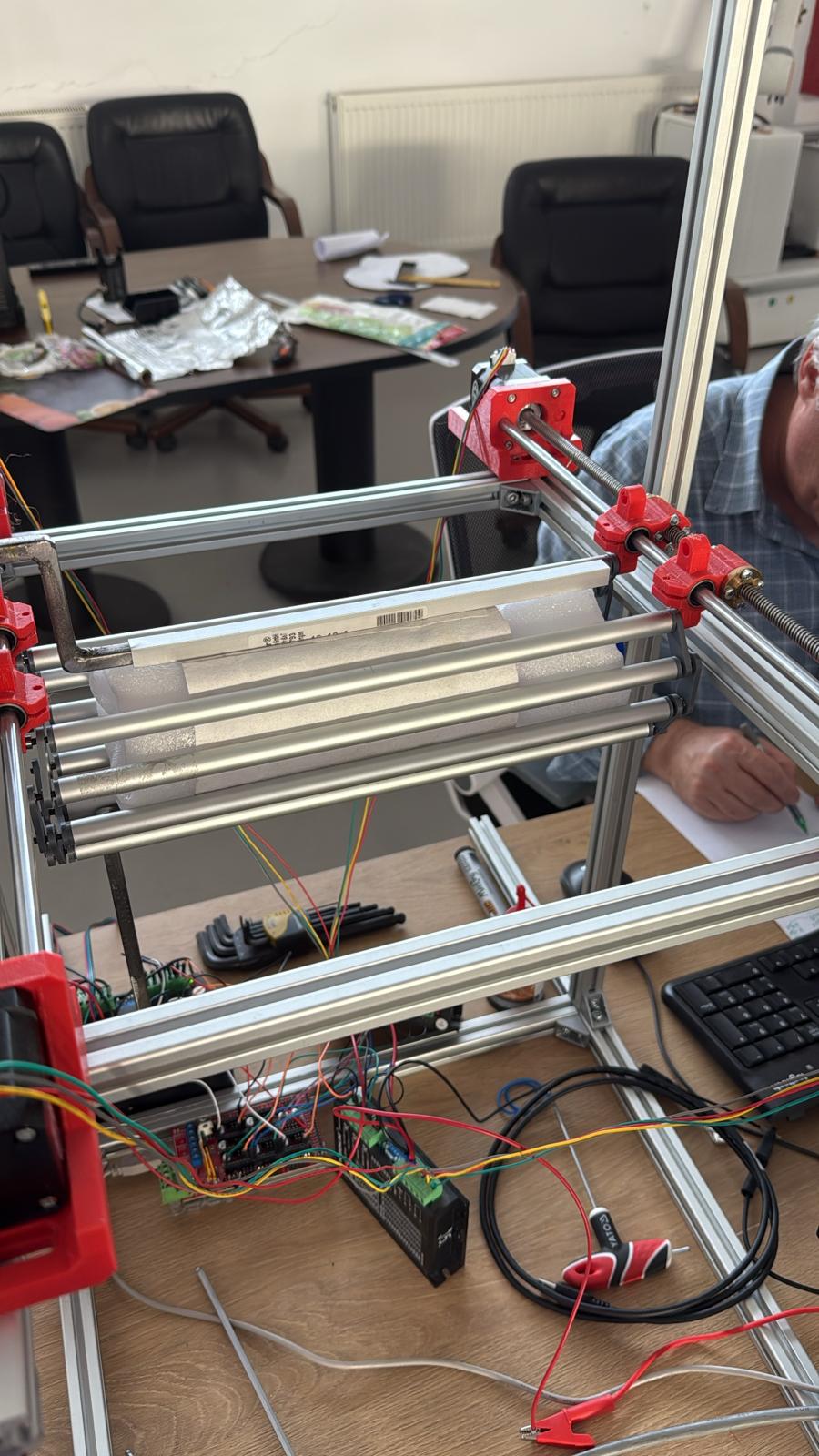

Shawarma Wrapping Device

- Developed core mechanics using timing belts, bearings, and a stepper/servo motion system

- Built and tested both the rolling subsystem and the extraction subsystem

- Evaluated multiple structural materials (aluminum, stainless steel, composites) for stiffness, hygiene, and manufacturability

- Experimented with various timing belts, stepper motors, servo drivers, and stepper motor drivers to optimize torque, precision, and repeatability

- Motion tests completed; next step is integrating sensors and force-feedback control for a fully automated wrapping sequence

Mechatronics & Food Handling

- Tested multiple sauce-dispensing systems to handle high-viscosity fluids (ketchup, garlic sauce), including gear pumps, peristaltic pumps, and diaphragm pumps

- Compared dosing precision, flow stability, and cleaning requirements to select the most reliable food-grade mechanism

Cooking & Thermal Control

- Modeled shawarma cooking parameters: radiator power, cone geometry, meat–radiator distance, angular velocity, and tangential surface speed

- Measured real cooking temperatures using a 160×120 radiometric thermal camera (TELEDYNE FLIR Lepton® 3.5) and fast-response thermocouple probes

- Collected thermal maps to validate our heat-transfer model and tune PID temperature regulation

- Created mechanical design drafts for an automated cooking module

- Evaluated how to upgrade existing commercial shawarma rotisserie machines for robotic integration

Control Systems — Operational

- Implemented real-time motion pipelines using EtherCAT (Inovance IS620N drivers, IgH EtherCAT Master, SOEM)

- Designed and built custom STM32 and Teensy control boards for motion control and sensor interfaces

- Tested Raspberry Pi CM4 and CM5, plus a range of China-made embedded compute modules for edge control

- Tested ROS 1 and ROS 2 (MoveIt, TF, planning pipelines) to evaluate kinematics and orchestration before designing our custom control layer

- Integrated robot SDKs for Borunte and Fairino platforms

- Evaluated multiple EtherCAT master stacks and communication topologies to optimize latency, determinism, and reliability

Workshop & Prototyping Pipeline — Ready

- MIG welding, machining, 3D printing

- PCB manufacturing via China

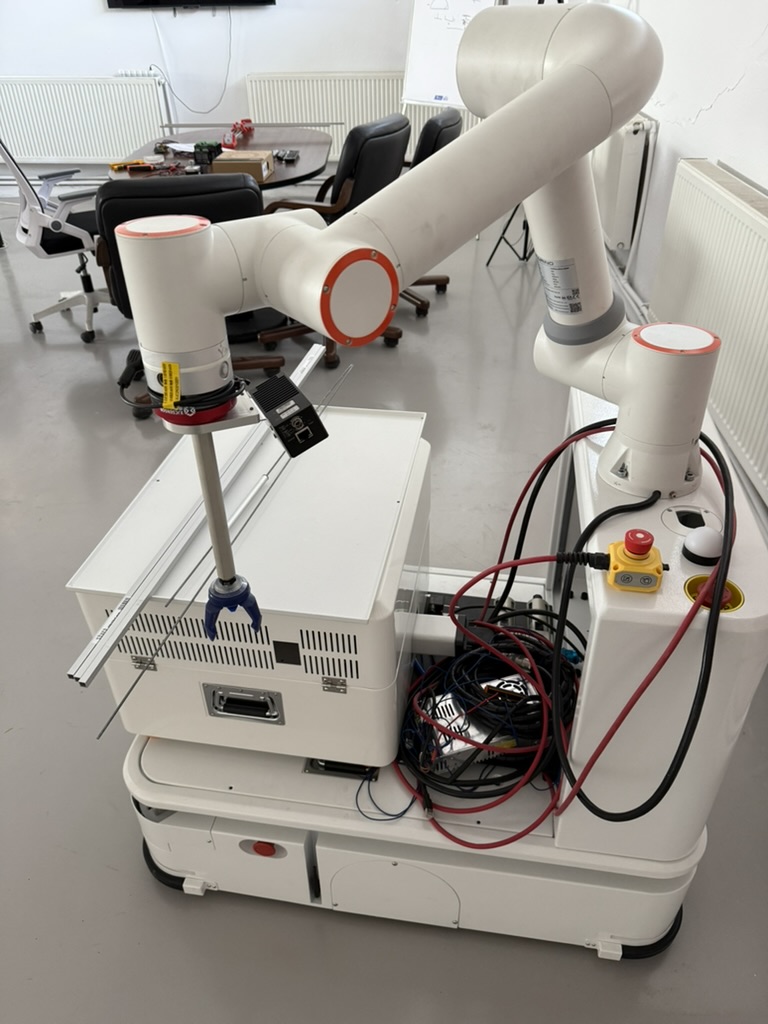

- AMR (Wellwit WAR100-SL) for internal transport

📸 Photo Gallery

📍 Why This Is Hard

Food automation is complex — it requires:

- robotics

- AI vision

- real-time motion

- mechanical engineering

- electronics

- control systems

- industrial design

- simulation

I’ve built all of these individually, then integrated them into working prototypes.

This lets me move 10× faster than teams that split these skills across 5–10 engineers.

👤 Founder

Gabriel Breahna

Industrial Engineer & Robotics, Software Development

Experience:

- Oracle (cloud + distributed systems)

- Homologated a 12.4-liter CNG engine at TÜV Prague (Euro 6), coordinating sensors, control systems, and safety validation

- Robotics: SCADA systems, EtherCAT, PLCs

- Vision, ML, 3D cameras, custom EOATs

- Custom STM32 devices manufactured in China

📈 Path to Market

- Deploy modules in a real shop (fryer → wrapper → full assembly line).

- Full automated shawarma shop in 24 months.

- Scale to pizza, burgers, fried chicken with the same modules.

- Containerized franchise expansion across Romania → EU → US.

🚀 Introduction